Overview of Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

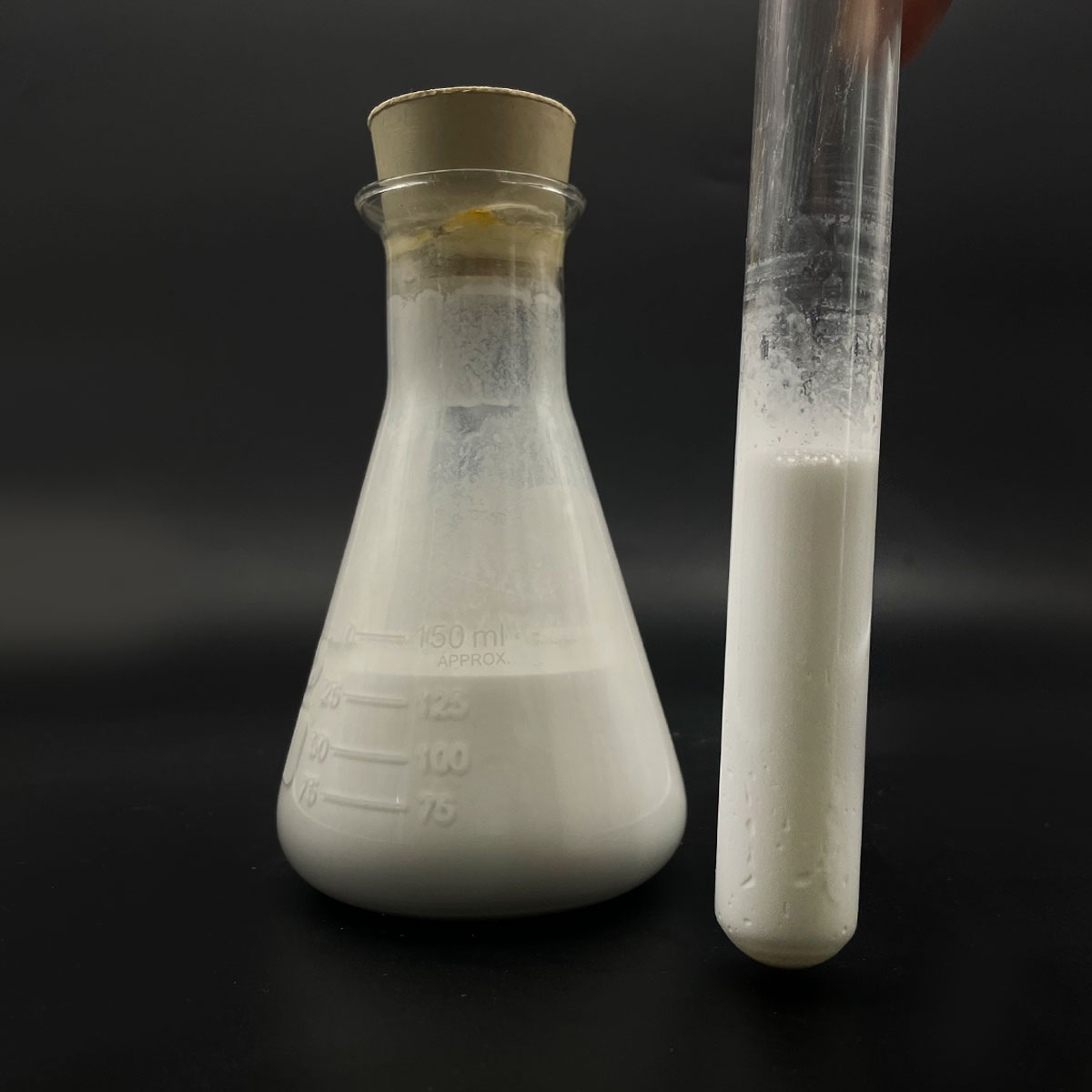

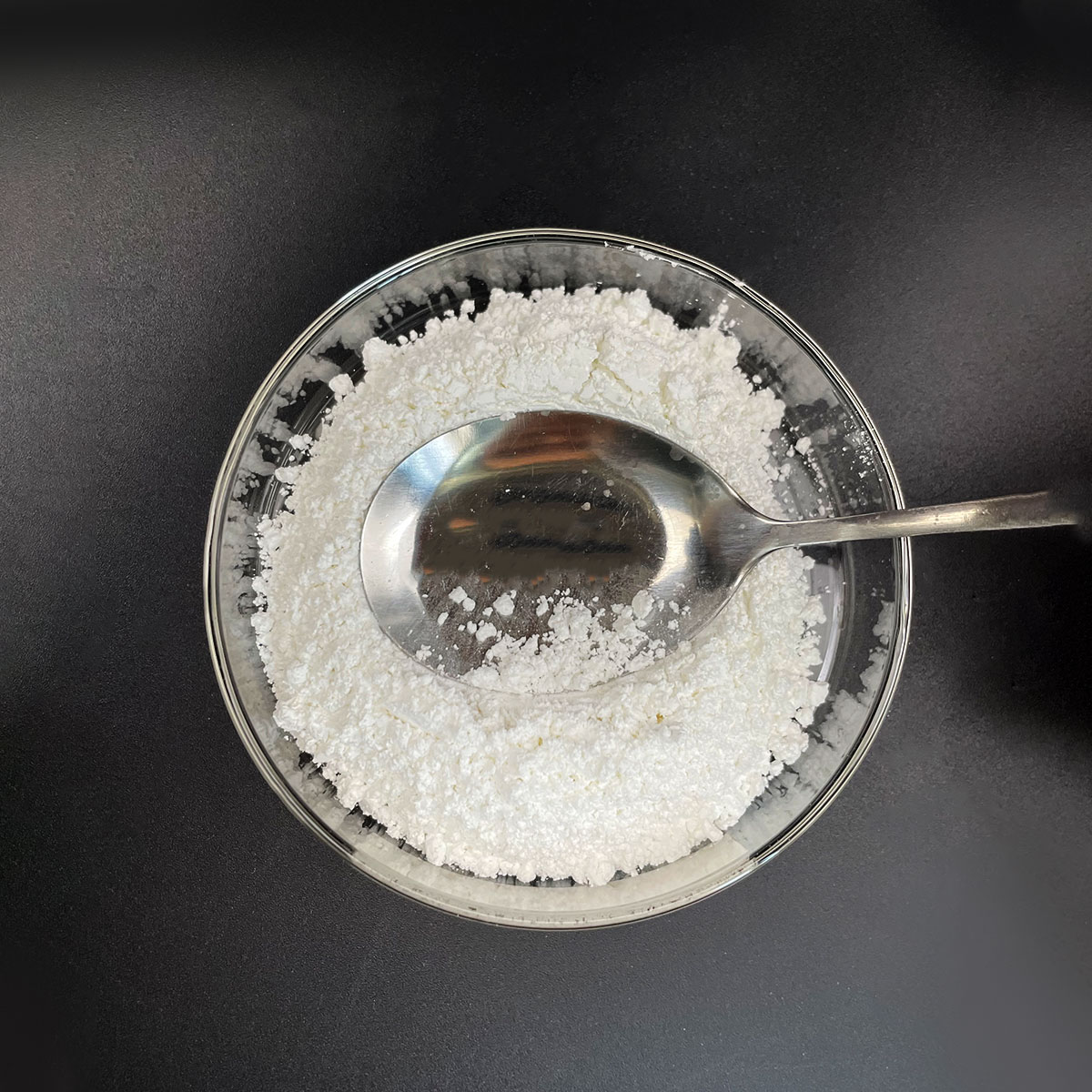

(Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels)

Specification of Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels

Spherical silver powder is a critical component in conductive silver pastes used for solar panel manufacturing, offering high electrical conductivity, thermal stability, and compatibility with screen-printing processes. Key specifications include:

**Particle Size and Distribution:** The powder typically has a controlled particle size range of 0.5–10 micrometers, ensuring uniform dispersion in the paste. Narrow particle size distribution (e.g., D50 ≈ 2–5 µm) minimizes voids and enhances conductivity.

**Purity:** High-purity silver (≥99.9%) is essential to prevent impurities from degrading electrical performance or causing oxidation. Trace elements like lead, iron, or copper are minimized (often <100 ppm).

**Morphology:** Spherical particles improve packing density, reduce surface oxidation, and enhance flow properties. Smooth surfaces minimize friction during printing, ensuring consistent paste application on solar cell electrodes.

**Surface Area:** A low surface area (0.5–1.5 m²/g) reduces reactivity and sintering temperature while maintaining mechanical strength in the final conductive layer.

**Tap Density:** High tap density (≥4.5 g/cm³) indicates dense particle packing, which improves conductivity and reduces the binder content required in the paste.

**Oxygen Content:** Low oxygen levels (<0.5%) prevent oxidation during sintering, ensuring stable conductivity and adhesion to silicon substrates.

**Electrical Conductivity:** Post-sintering, the powder achieves a bulk resistivity of ≤5 µΩ·cm, critical for efficient charge collection in solar cells.

**Compatibility:** The powder is engineered to blend seamlessly with organic vehicles (e.g., resins, solvents) to form stable pastes with optimal viscosity, printability, and adhesion.

**Application Performance:** In silver pastes, the powder enables low-temperature sintering (≤300°C), strong interfacial adhesion to silicon, and minimal contact resistance. It supports fine-line printing for busbars and fingers, maximizing light absorption and energy conversion efficiency.

**Environmental Stability:** Resistant to humidity, UV exposure, and thermal cycling, ensuring long-term reliability in outdoor solar panel installations.

**Certifications:** Compliant with RoHS, REACH, and other environmental regulations for sustainable manufacturing.

This specification set ensures spherical silver powder enhances the performance, durability, and cost-efficiency of silver pastes in photovoltaic applications, directly contributing to higher solar cell efficiency and energy output.

(Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels)

Applications of Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels

Spherical silver powder is a critical component in the formulation of conductive silver pastes used in solar panel manufacturing, particularly in photovoltaic (PV) cells. As a conductive filler, it plays a vital role in creating efficient electrical pathways within the front and rear electrodes of solar cells, ensuring optimal energy conversion. The spherical shape of the silver particles offers distinct advantages over irregularly shaped powders, enhancing both the performance and reliability of silver pastes.

One key application of spherical silver powder lies in its ability to form densely packed conductive networks. The uniform geometry of spherical particles minimizes voids and gaps in the silver paste, reducing electrical resistance and improving current collection efficiency. This is especially critical for the front-side metallization of silicon solar cells, where high conductivity and fine-line printing capabilities are required to maximize light absorption while minimizing shading losses. The smooth surface of spherical particles also ensures better dispersion in organic vehicles and glass frits, enabling homogeneous pastes that can be screen-printed with precision.

Additionally, spherical silver powder enhances the sintering behavior of silver pastes during the high-temperature firing process. The uniform particle size distribution promotes consistent melting and bonding between adjacent particles, resulting in robust electrical contacts with low contact resistance. This improves the long-term durability of solar panels, even under harsh environmental conditions.

Another advantage is the reduced silver content required to achieve target conductivity levels. Spherical particles offer higher surface area-to-volume ratios compared to flake or dendritic powders, allowing for efficient percolation pathways at lower loading levels. This not only lowers material costs but also reduces the risk of microcracks caused by paste shrinkage during drying and sintering.

In advanced solar technologies like PERC (Passivated Emitter and Rear Cell) and heterojunction cells, spherical silver powder enables ultra-fine grid lines and improved adhesion to textured silicon surfaces. This contributes to higher conversion efficiencies and energy output. By optimizing light capture and electron transport, spherical silver powder supports the development of next-generation solar panels that align with global renewable energy goals. Its role in enhancing conductivity, printability, and cost-effectiveness makes it indispensable in the pursuit of sustainable solar solutions.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels

**What makes spherical silver powder ideal as a conductive filler in silver paste for solar panels?**

Spherical silver powder offers high electrical conductivity, uniform particle distribution, and excellent flowability, which ensures even dispersion in silver paste. Its spherical shape minimizes gaps between particles, creating dense conductive networks when sintered. This enhances current collection efficiency in solar cells, directly improving energy conversion rates. The smooth surface of spherical particles also reduces paste viscosity, enabling precise screen printing for fine grid lines on solar panels.

**How does spherical silver powder improve the conductivity of silver paste?**

The spherical shape allows particles to pack tightly, reducing interstitial voids and forming continuous conductive pathways. High-purity silver (≥99.9%) ensures minimal impurities that could hinder electron flow. During sintering, spherical particles fuse uniformly, lowering contact resistance. This results in higher conductivity compared to irregularly shaped powders, which create uneven interfaces and resistive barriers.

**What particle size range is optimal for spherical silver powder in solar applications?**

Particle sizes between 0.5–10 micrometers are commonly used. Smaller particles (submicron to 3 µm) increase surface area, enhancing sintering activity and adhesion to silicon wafers. However, overly fine powders may agglomerate or increase paste viscosity. Larger particles (5–10 µm) improve paste flow for thicker lines but reduce resolution. A balanced mix of sizes ensures optimal printability, conductivity, and mechanical strength in metallization layers.

**Does spherical silver powder resist oxidation or tarnishing in solar panels?**

Pure silver is inherently oxidation-resistant under standard environmental conditions. Spherical powders, with smooth surfaces and minimal defects, further reduce oxidation risks compared to flake or irregular powders. However, sulfur-containing environments can cause tarnishing (silver sulfide formation). Encapsulation within the solar panel’s EVA layer and using anti-tarnish coatings in the paste mitigate this issue, ensuring long-term stability.

**Why is spherical silver powder cost-effective despite its premium price?**

Though spherical powder is pricier than alternatives, its superior packing density and conductivity reduce the amount needed per watt of solar cell output. This lowers material costs per unit efficiency. Additionally, its printability minimizes waste during screen printing, while high reliability extends panel lifespan. These factors offset initial costs, making it a cost-efficient choice for high-performance, large-scale solar production.

(Spherical Silver Powder as Conductive Filler in Silver Paste for Solar Panels)