Overview of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

(Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200)

Parameters of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200

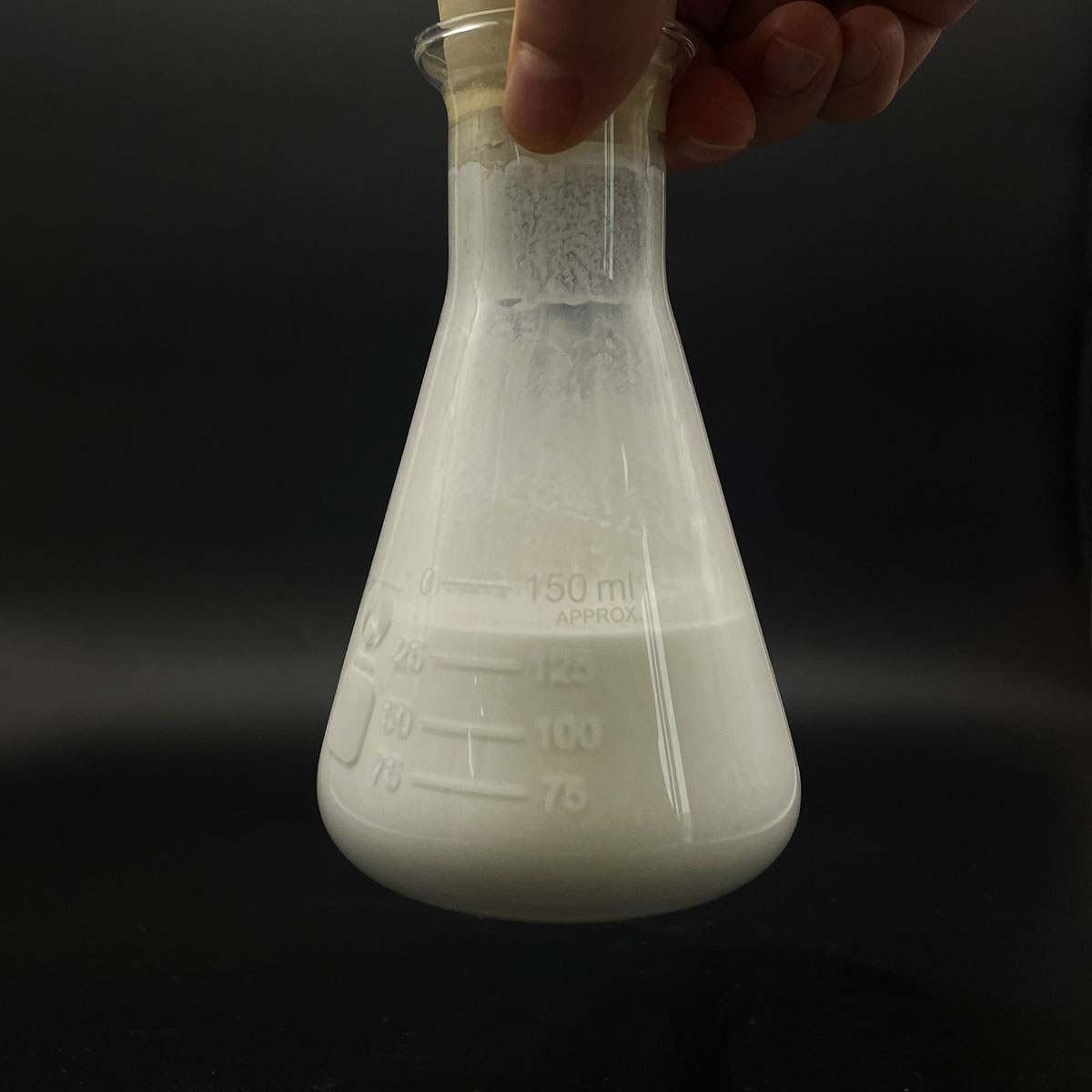

LF6200 is a nonionic surfactant that is widely used in cutting, grinding and fluid additives. It has a mild surfactant density and high ionic strength, which makes it suitable for use in many applications where the required level of hydrophobicity and solubility is moderate.

In liquid formulations, LF6200 typically acts as a thickener or emulsifier, helping to stabilize emulsions and reduce droplets formation during blending and mixing. It can also be used to enhance the compatibility between different components in a mixture.

When used as a cutting or grinding fluid additive, LF6200 helps to reduce friction and improve blade performance by creating a slippery surface that minimizes the amount of energy needed to cut through materials. It can also help to prevent wear and tear on blades by reducing the formation of static charges that can cause damage over time.

Overall, LF6200 is a versatile and effective surfactant that is widely used in various industries and applications due to its gentle and effective cleaning properties. Its nonionic nature makes it environmentally friendly and safe to use.

(Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200)

Applications of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200

-

Electronic Chemicals: In semiconductor manufacturing for cleaning, etching, and photoresist stripping, requiring ultra-purity and high performance.

-

Aerospace and Defense: Used in coatings, lubricants, and cleaning agents that need to withstand extreme environments and meet rigorous performance and safety standards.

-

Medical Devices and Pharmaceuticals: As coatings, detergents, and emulsifiers in applications where biocompatibility and regulatory compliance are paramount.

-

Oilfield Services: In drilling fluids, stimulation fluids, and production chemicals where high temperature, high pressure, and corrosion resistance are essential.

-

Printing Inks and Coatings: To improve ink adhesion, flow properties, and substrate wetting in specialized printing technologies and high-end coatings.

-

Home Care and Institutional Cleaning: In formulations requiring specific performance characteristics, such as low-foaming, hard surface cleaning, or environmentally friendly credentials.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200

Q: Is Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200 more expensive than commodity surfactants?

A: Yes, due to its specialized design, advanced chemistry, and often lower volume production, specialty surfactants typically command a higher price.

Q: Can Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200 be customized for specific customer needs?

A: Absolutely, one of the defining features of Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200 is their customization to meet the precise performance or regulatory requirements of individual customers or applications.

Q: Are all specialty surfactants environmentally friendly?

A: Many specialty surfactants are developed with eco-friendliness in mind, using renewable feedstocks or designed for biodegradability, but this characteristic is not universal and depends on the specific product and its intended use.

Q: Are there any limitations to using Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200?

A: Their specialized nature can sometimes limit availability, increase cost, and require more in-depth knowledge for proper handling and formulation compared to general-purpose surfactants.

Q: How does one choose the right specialty surfactant for a specific application?

A: Selection involves considering the required performance attributes, compatibility with other ingredients, regulatory requirements, and consulting with surfactant suppliers who can provide technical expertise and samples for testing.

(Readily Biodegradable Solubility In liquid Formulations Nonionic Surfactant Cutting Grinding Fluid Additives LF6200)