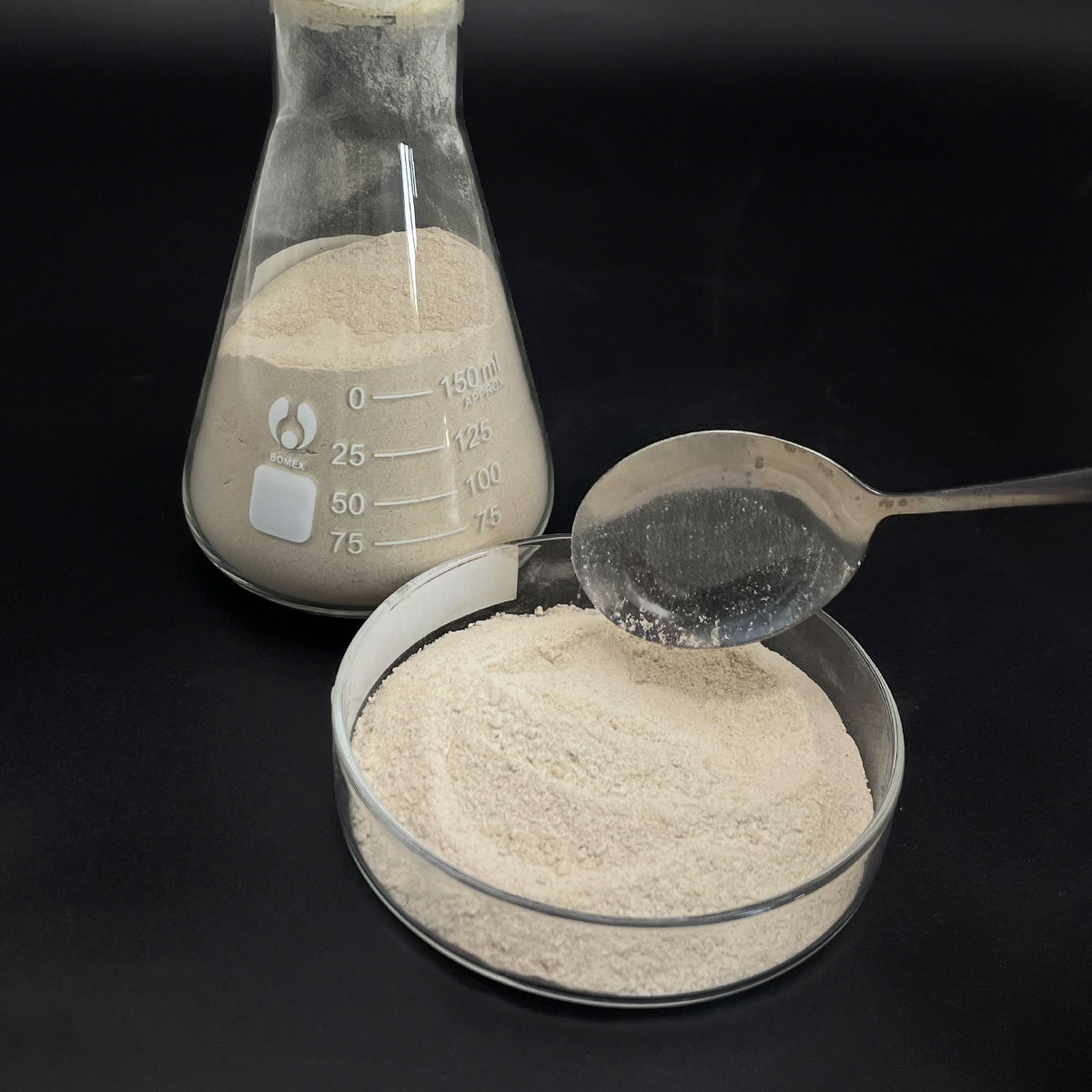

Overview of Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte)

Parameters of Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte

The properties of organic high polymer dry powder polyacrylamide PAM Anionic And Cationic polyelectrolyte parameters depend on the specific formulation and application. However, here is a general description of some key parameters:

1. Molecular weight: The molecular weight of the polymer plays a significant role in determining its effectiveness in polymerization. Generally, higher molecular weights of polymer can improve the synthesis yield, but may also lead to longer polymer chains and higher costs.

2. Formula length: The formula length of the polymer determines its strength, stability, and viscosity. A longer formula length results in stronger bonds and more uniform distribution of fibers, while a shorter formula length can result in lower bond strengths and behavior.

3. Solubility: The solubility of the polymer depends on its surface area, which in turn affects its ability to interact with water. Higher surface areas enable the polymer to dissolve faster than simpler polymers due to their low intermolecular interactions.

4. Chain growth: The chain growth of the polymer also affects its processingability. A shorter chain growth process will require more material for production and may result in higher cost.

5. Reusability: The reusability of the polymer also depends on its processing method and preference. For example, certain types of polymers, such as honor systems, may be better suited for printing or manufacturing due to their high availability and flexibility.

6. Sustainability: The sustainability of the polymer can also impact its application. For example, eco-friendly materials that use less water, energy, and raw materials can help reduce the environmental impact of production and use.

(Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte)

Applications of Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte

-

Household Cleaners: In detergents, dishwashing liquids, and laundry soaps for their strong cleaning and degreasing abilities.

-

Personal Care Products: Found in shampoos, bath soaps, and toothpaste for their cleansing and foaming properties.

-

Textile Processing: Used as wetting agents, detergents, and emulsifiers in fabric processing, dyeing, and finishing.

-

Agriculture: As adjuvants in pesticide formulations to improve spreading and sticking properties on plant surfaces.

-

Metal Working Fluids: As emulsifiers and corrosion inhibitors in metalworking fluids and industrial cleaning solutions.

-

Oilfield Chemicals: Employed in drilling muds and oil spill dispersants due to their ability to reduce surface tension and emulsify oils.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte

Q: Is Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte suitable for all skin types?

A: While commonly used, some anionic surfactants can be harsh on sensitive skin due to their strong cleansing action. Milder forms or combinations with other surfactant types are recommended for sensitive formulations.

Q: Does Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte biodegrade easily?

A: Biodegradability varies with the specific type of anionic surfactant. Linear alkylbenzene sulfonates (LAS) and alcohol ethoxysulfates (AES) are examples of biodegradable anionic surfactants commonly used in environmentally friendly products.

Q: Why does Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte foam so much?

A: Their molecular structure allows them to reduce the surface tension of water significantly, facilitating the formation of stable air bubbles and thus producing foam.

Q: Is Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte compatible with hard water?

A: Hard water can reduce the effectiveness of anionic surfactants by forming insoluble salts. However, builders like sodium tripolyphosphate are often added to counteract this effect.

Q: Are there any environmental concerns associated with Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte?

A: Yes, certain anionic surfactants can persist in the environment or be toxic to aquatic life. Regulations exist to limit the use of harmful types, and research focuses on developing more eco-friendly alternatives.

(Organic High Polymer Dry Powder Polyacrylamide PAM Anionic And Cationic polyelectrolyte)