Overview of Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

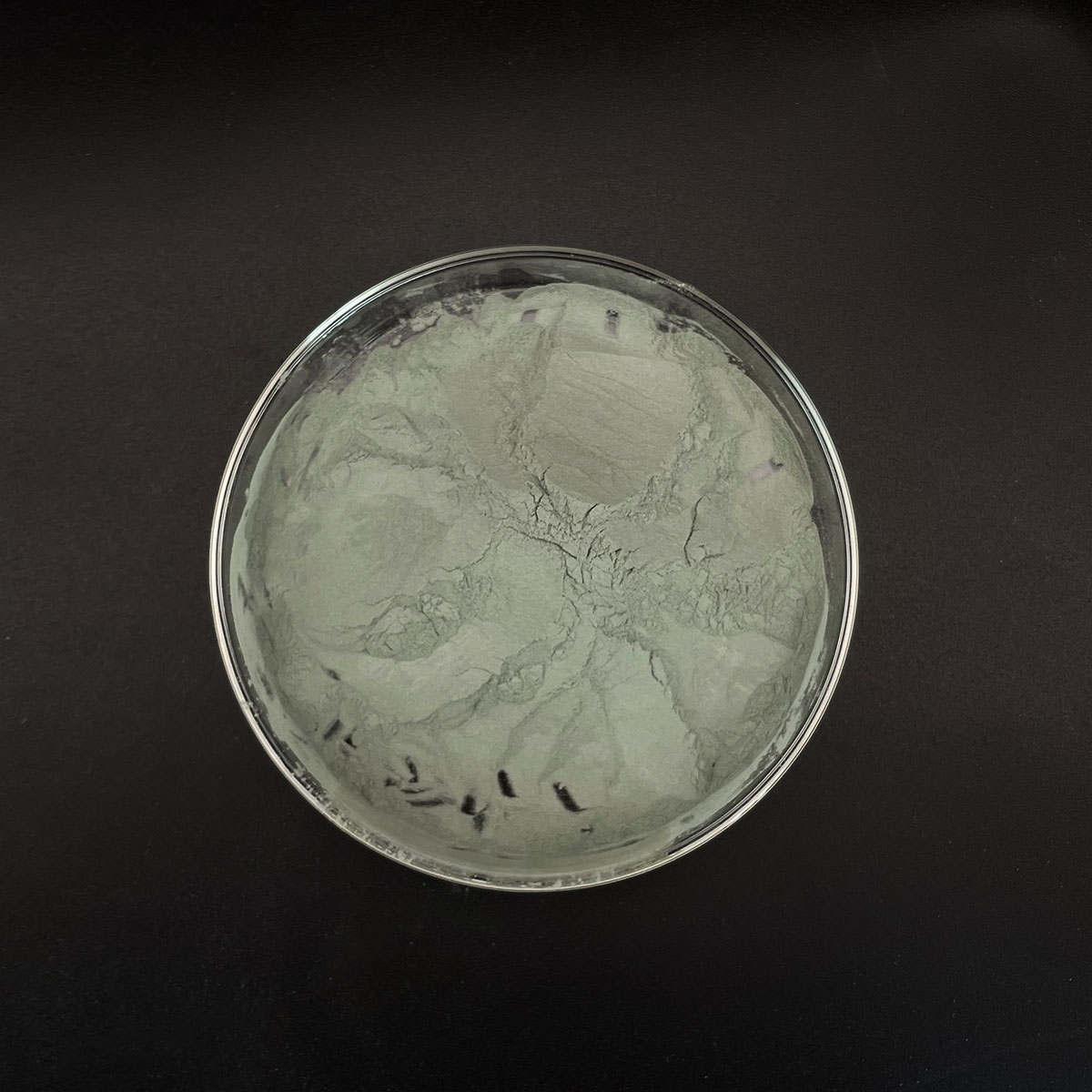

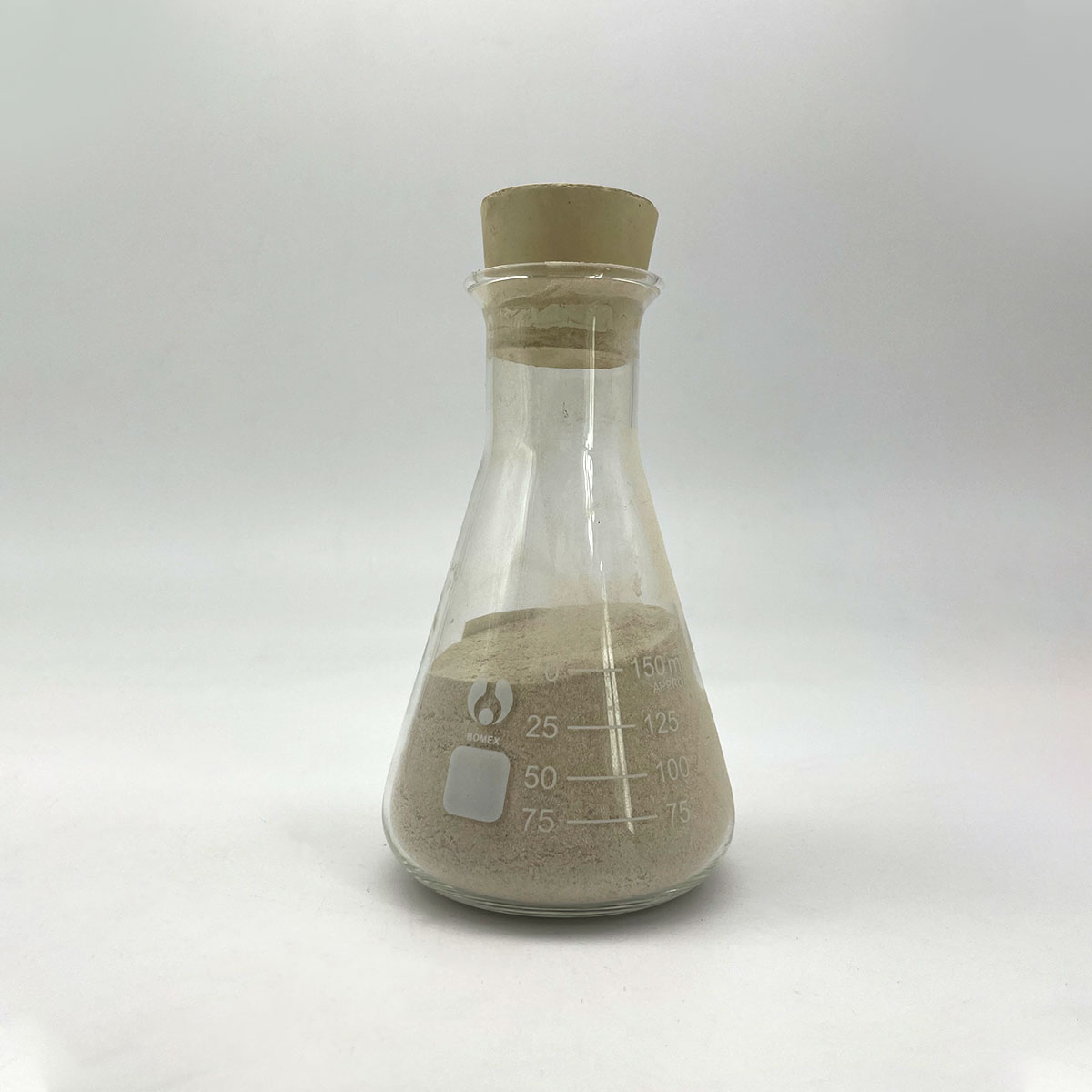

(Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside)

Specification of Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside

Non-spherical silver powder is an essential component in silver paste formulas for the backside of solar batteries, making it possible for effective electrical conductivity, attachment, and longevity. This specific powder is engineered to optimize performance in photovoltaic or pv applications, particularly for screen-printing processes. Below are the key specifications and qualities:

** Bit Morphology **: The powder features irregular, non-spherical shapes such as flake-like, dendritic, or agglomerated frameworks. This morphology boosts surface area and interparticle get in touch with, enhancing conductivity while lowering the requirement for too much resin material in the paste.

** Particle Size Distribution **: Managed particle size guarantees harmony in the paste. Typical requirements consist of a D50 (average bit size) ranging in between 1.0– 3.0 micrometers, with a narrow distribution (D90 < 6.0 μm) to prevent clogging throughout printing and guarantee smooth movie formation.

** Pureness **: High pureness (≥ 99.9% Ag) decreases contaminations that might weaken electrical efficiency or trigger oxidation. Trace element levels (e.g., Pb, Fe, Cu) are snugly managed to

(Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside)

Applications of Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside

Non-spherical silver powder is an important element in silver paste formulations used for the behind electrodes of solar cells, playing a crucial role in enhancing efficiency, longevity, and expense efficiency. Unlike conventional round bits, non-spherical silver powder features irregular shapes, such as flakes or dendrites, which provide special advantages in conductive applications.

The main application of non-spherical silver powder in behind silver paste hinges on its capability to develop highly conductive networks. The rugged edges and raised surface of non-spherical particles produce more contact points in between nearby fragments throughout the sintering process. This leads to lower electric resistance, boosting electron collection performance and general solar cell conversion prices. In addition, the interlocking nature of these bits boosts mechanical attachment to the silicon substratum, reducing delamination risks under thermal tension or environmental direct exposure.

Another essential advantage is the decrease of silver material needed to achieve optimal conductivity. The uneven morphology enables tighter packaging and reliable percolation paths, making it possible for makers to make use of much less product without compromising performance. This directly decreases manufacturing expenses, a vital consider the affordable solar market. In addition, non-spherical powders frequently exhibit improved compatibility with glass frit– a binder in silver paste– making certain consistent diffusion and steady firing processes. This compatibility decreases gaps and issues, bring about smoother electrode surface areas and far better long-lasting reliability.

Non-spherical silver powder likewise adds to environmental sustainability. By enhancing material use and reducing waste, it supports greener production methods. Its improved toughness guarantees solar cells preserve efficiency over expanded durations, even in extreme outdoor problems, thus prolonging product lifespans and minimizing replacement regularity.

In recap, non-spherical silver powder boosts backside silver paste performance by enhancing conductivity, adhesion, and cost-effectiveness while supporting sustainable production. These features make it vital for progressing solar cell innovation, aligning with international needs for reliable, budget friendly renewable energy options.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside

**1. What is non-spherical silver powder, and why is it used in solar cell backside silver paste?**

Non-spherical silver powder refers to irregularly shaped particles (flakes, rods, or dendritic structures) used as a conductive filler in silver paste for solar cells. Its unique morphology enhances electrical conductivity, adhesion, and mechanical interlocking with the substrate, ensuring reliable performance in the backside electrodes of solar cells. This improves efficiency and durability under environmental stress.

**2. How does non-spherical silver powder improve solar cell performance compared to spherical powder?**

Non-spherical particles have higher surface area and jagged edges, which create stronger bonds within the paste and with the solar cell surface. This reduces resistivity, minimizes silver usage (lower cost), and enhances current collection. The irregular shape also improves printability and sintering behavior, leading to better electrode line resolution and long-term stability in harsh operating conditions.

**3. What factors influence the quality of non-spherical silver powder for silver paste?**

Key factors include particle size distribution, shape consistency, surface purity, and oxidation resistance. Tight control over particle size ensures uniform conductivity, while high purity (≥99.9%) prevents contamination. Surface treatments (e.g., anti-agglomeration coatings) and optimized morphology are critical to maintain dispersion stability in the paste and prevent voids or cracks during sintering.

**4. How should non-spherical silver powder be stored and handled?**

Store in airtight, moisture-proof containers at room temperature (15–25°C) away from direct sunlight. Avoid exposure to humidity, high temperatures, or corrosive chemicals to prevent oxidation or agglomeration. Use gloves and inert gas purging during handling to minimize contamination. Always follow safety guidelines for metal powders, including proper ventilation and grounding to avoid electrostatic discharge.

**5. Is non-spherical silver powder compatible with different types of silver paste formulations?**

Yes, it is adaptable to organic- or glass-frit-based pastes. The powder’s morphology and surface chemistry can be tailored to match specific binder systems, solvents, or sintering profiles. Manufacturers often optimize particle size and shape to align with printing methods (screen, inkjet) and substrate materials (silicon, PERC, TOPCon). Compatibility testing is recommended to ensure performance in targeted applications.

(Non-Spherical Silver Powder Used in Silver Paste for Solar Cells Backside)