Overview of Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8)

Specification of Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8

Product Call: Hot Ing Silicone Oil (OH-Terminated Silicone Polymer).

CAS Number: 70131-67-8.

Basic synonyms: Hydroxyl-terminated polydimethylsiloxane, OH-PDMS, Silicone fluid.

** Chemical Framework and Make-up **.

OH-terminated silicone polymer is a linear polydimethylsiloxane (PDMS) chain with hydroxyl (- OH) groups at both ends. Its molecular formula is usually HO [( CH3) 2SiO] nH, where “n” denotes the degree of polymerization, determining molecular weight and viscosity.

** Physical Properties **.

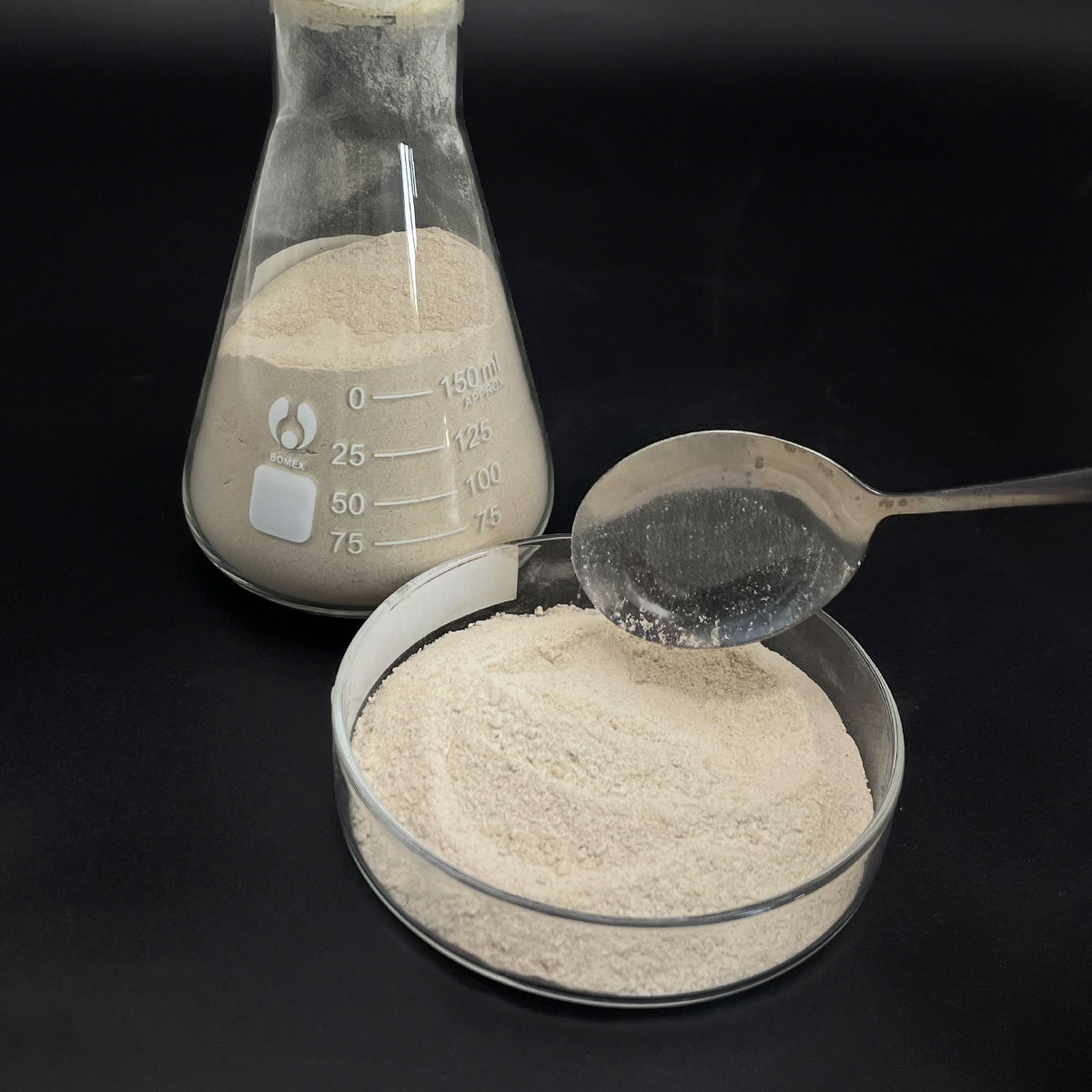

– ** Look **: Clear, colorless to pale-yellow viscous liquid.

– ** Viscosity **: Adjustable based on molecular weight, varying from 10 cSt to 100,000 cSt at 25 ° C.- ** Thickness **: ~ 0.97– 0.98 g/cm ³ at 25 ° C.- ** Refractive Index **: ~ 1.400– 1.405.

– ** Blink Point **: > 300 ° C( based on molecular weight).

– ** Solubility **: Insoluble in water, methanol, or ethanol; soluble in hydrocarbons (toluene, hexane) and chlorinated solvents.

** Key Requirements **.

– ** Hydroxyl Web content **: 0.1– 1.5% (flexible per synthesis).

– ** Molecular Weight **: 500– 500,000 g/mol (personalized).

– ** Thermal Security **: Steady from -50 ° C to +250 ° C, with temporary resistance as much as 300 ° C.- ** Volatile Material **: ≤ 1.0% (after home heating at 150 ° C for 24 hours).

** Applications **.

– ** Cosmetics/Personal Treatment **: Made use of as a skin-conditioning representative, emollient, or hair treatment additive for smooth texture and sparkle.

– ** Industrial Lubricants **: High-temperature lubricating substance for plastics, rubber, and steel surface areas.

– ** Launch Agents **: Non-stick layers for molds in vehicle, aerospace, or food-grade applications.

– ** Chemical Intermediate **: Functions as a forerunner for modifying silicones (e.g., implanting, crosslinking) in adhesives, coatings, or elastomers.

** Key Features **.

– Excellent thermal and oxidative stability.

– Reduced surface stress and high water repellency.

– Non-reactive with the majority of chemicals; retains adaptability at low temperatures.

– Compatible with organic polymers for hybrid product synthesis.

** Storage space and Handling **.

Shop in sealed containers away from wetness, direct sunshine, and high temperatures. Shelf life: 2 years when saved listed below 30 ° C.

** Safety and security and Environmental **.

Safe, non-irritating to skin (at suggested concentrations), and non-flammable. Dispose of according to regional policies. Not identified as dangerous under OSHA or GHS.

** Regulatory Conformity **.

Complies with REACH, FDA (for details grades), and RoHS standards. Certificates of Analysis (CoA) and Safety Information Sheets (SDS) available upon demand.

This product is personalized in viscosity, molecular weight, and hydroxyl material to satisfy details commercial or formulation requirements. For technological inquiries or mass orders, call the manufacturer straight.

(Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8)

Applications of Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8

Hot in silicone oil OH-terminated silicone polymer (CAS: 70131-67-8) is a functional product commonly recognized for its thermal stability, adaptability, and chemical inertness. This hydroxyl-terminated polydimethylsiloxane (PDMS) exhibits low volatility, high-temperature resistance, and compatibility with diverse industrial processes, making it valuable throughout multiple markets. A key application is as a warm transfer liquid in commercial systems, electronic devices cooling down, and solar thermal arrangements, where it efficiently handles temperature level changes without breaking down. Its secure viscosity throughout a wide temperature array guarantees constant performance in severe problems. In high-temperature lubrication, this silicone oil decreases rubbing and wear in engines, bearings, and equipment, keeping smooth procedure under thermal tension. It also serves as a processing help in rubber and plastic production, functioning as a release agent or plasticizer throughout vulcanization or molding, improving flow and protecting against attachment to mold and mildews. The reactive hydroxyl teams make it possible for crosslinking in heat-cured adhesives and sealers, developing durable bonds for vehicle, aerospace, and construction applications immune to thermal biking. In electronics, it works as a protective finishing or encapsulant, protecting parts from warmth, dampness, and mechanical stress and anxiety. The fabric sector uses it for heat-resistant material coverings, improving longevity in safety equipment and industrial products. Additionally, it is employed in lab settings as a stable heating tool in warm oil bathrooms and in medical gadget production, where high-temperature sanitation is called for. Its chemical inertness and non-toxic nature make it suitable for specialized cosmetics, such as heat-protective hair items. The polymer’s versatility originates from its equilibrium of thermal strength, compatibility with additives, and ability to improve material efficiency under stress. These features position OH-terminated silicone polymer as a critical part in sectors demanding reliability under extreme thermal and mechanical conditions, offering options that focus on efficiency, safety and security, and longevity.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8

Hot Ing Silicone Oil OH-Terminated Silicone Polymer (CAS: 70131-67-8) is a versatile material with hydroxyl groups at its chain ends, enabling crosslinking for enhanced performance. Below are five FAQs about this product: **1. What are the primary applications of OH-Terminated Silicone Polymer?** This polymer is widely used in cosmetics, personal care products, lubricants, release agents, and industrial coatings. Its flexibility, heat resistance, and water-repellent properties make it ideal for skincare formulations, anti-foaming agents, and high-temperature-resistant coatings. It also serves as a precursor in silicone rubber and medical device manufacturing. **2. Is it safe for direct skin contact?** Yes, when properly formulated, it is generally safe for skin contact. It is non-irritating and non-sensitizing, passing dermatological testing. However, safety depends on concentration and final product composition. Always review safety data sheets and conduct patch tests for consumer products. **3. How should it be stored to maintain stability?** Store in a cool, dry place (15–25°C) away from moisture, direct sunlight, and extreme temperatures. Keep containers tightly sealed to prevent contamination or premature crosslinking due to humidity. Proper storage ensures a shelf life of up to 12 months. **4. Is it compatible with other chemicals or materials?** It is compatible with most organic polymers, plastics, and rubbers. However, avoid mixing with strong acids, bases, or catalysts without prior testing, as these may trigger unintended reactions. Compatibility testing is recommended for specific formulations. **5. How does it differ from non-reactive silicone oils?** Unlike non-reactive silicone oils, the hydroxyl groups allow chemical crosslinking, enabling adhesion, curing, and integration into networks for durable coatings or elastomers. This reactivity makes it suitable for applications requiring enhanced mechanical strength or thermal stability compared to inert silicone fluids.

(Hot ing Silicone Oil Oh-Terminated Silicone Polymer/CAS: 70131-67-8)