Overview of High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

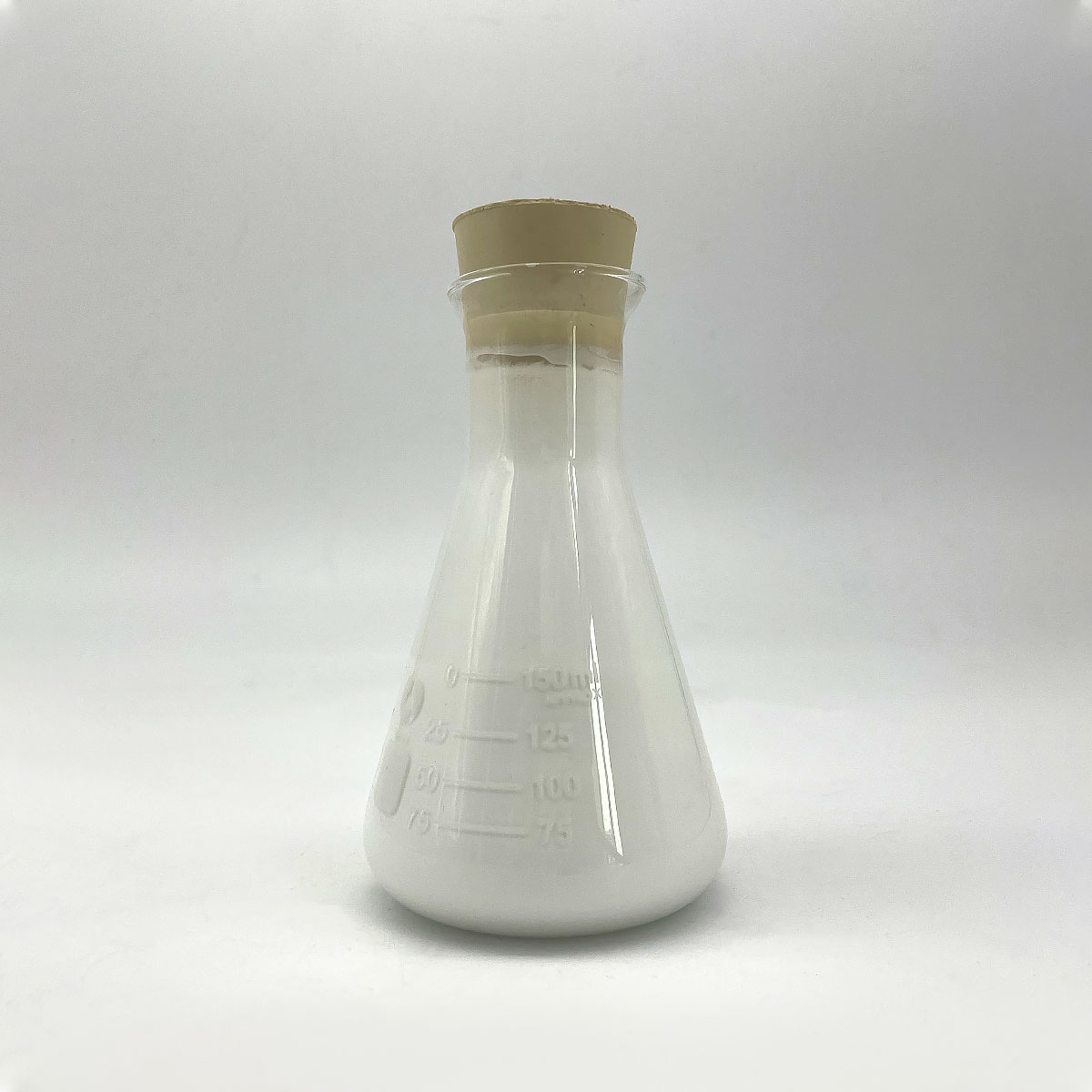

(High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid)

Specification of High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid

High Thickness 107 Polymer Hydroxyl Silicone Oil, also known as Polymer Terminated Silicone Fluid, is a high-performance silicone polymer crafted for industrial applications requiring thermal stability, lubrication, and compatibility with organic and inorganic systems. This hydroxyl-terminated silicone oil features a linear polydimethylsiloxane (PDMS) foundation with reactive hydroxyl (- OH) teams at both termini, allowing crosslinking in polymer formulas. Its high viscosity and tailored molecular framework make it ideal for use as a base fluid, additive, or modifier in coverings, adhesives, sealants, and elastomers.

** Trick Specifications: **.

– ** Chemical Composition: ** Polydimethylsiloxane (PDMS) with hydroxyl end teams.

– ** Appearance: ** Transparent, anemic to pale-yellow thick liquid.

– ** Thickness (25 ° C): ** 10,000– 100,000 mPa · s (personalized based upon polymerization level).

– ** Hydroxyl Material: ** 0.1– 1.0 mmol/g (flexible per synthesis specifications).

– ** Molecular Weight: ** 50,000– 200,000 g/mol (differs with viscosity grade).

– ** Density (25 ° C): ** 0.97– 1.02 g/cm ³.

– ** Refractive Index (25 ° C): ** 1.400– 1.410.

– ** Blink Point: ** > 300 ° C( non-flammable under basic conditions).

– ** Thermal Stability: ** Secure across -50 ° C to +250 ° C, with minimal degradation.

– ** Volatility: ** Low volatility as a result of high molecular weight.

– ** Solubility: ** Insoluble in water, ethanol, or methanol; soluble in hydrocarbons, chlorinated solvents, and silicone liquids.

** Applications: **.

Made use of as a thickening representative, lube, or damping fluid in automobile, aerospace, and equipment elements. Boosts versatility and warm resistance in silicone rubber, adhesives, and sealers. Works as a release representative in mold production and a conditioning agent in textiles. Compatible with fillers, resins, and treating agents (e.g., silanes, alkoxysilanes) for customized crosslinking.

** Handling & Storage space: **.

Store in airtight containers at 5– 30 ° C, far from wetness and oxidizing agents. Service life exceeds one year under appropriate problems. Usage PPE throughout managing to prevent call with eyes or skin.

This silicone liquid combines high thickness, reactivity, and toughness, making it a versatile product for advanced industrial and manufacturing procedures.

(High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid)

Applications of High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid

High Thickness 107 Polymer Hydroxyl Silicone Oil and Polymer Terminated Silicone Fluid are functional silicone-based materials with specialized applications throughout diverse markets. Their one-of-a-kind chemical frameworks– hydroxyl reactivity in the former and tailored terminal teams in the last– allow performance-driven solutions.

In adhesives and sealers, High Viscosity 107 Polymer Hydroxyl Silicone Oil serves as a crosslinking agent, boosting bond stamina and adaptability. Its hydroxyl teams assist in reactions with various other polymers, producing long lasting networks resistant to temperature level changes and environmental stress. It additionally functions as a plasticizer in rubber and plastics, boosting elasticity while preserving structural integrity.

The fabric sector leverages this hydroxyl-functional silicone oil as a material conditioner and water-repellent finish. Its high viscosity makes sure long-lasting lubrication, lowering fiber rubbing and boosting fabric resilience. In cosmetics, it passes on a silky appearance to hair conditioners and skin lotions, providing moisture retention without greasiness.

Polymer Ended Silicone Liquid, with inert terminal groups like methyl or phenyl, excels in high-temperature lubrication for industrial equipment and automobile parts. Its thermal stability reduces break down under extreme problems, expanding equipment life. In finishings, it gives water resistance, UV protection, and gloss improvement for automobile paints and architectural surfaces.

Electronic devices benefit from its dielectric residential or commercial properties, where it safeguards sensitive parts from moisture and electric damages. It also aids in thermal management, dissipating warm in LEDs and power modules. Clinical gadget suppliers utilize it for lubricious finishes on catheters and surgical tools, guaranteeing biocompatibility and smooth procedure.

In building, both silicones contribute to weather-resistant sealants and anti-foaming agents for cement. Polymer Ended Silicone Fluid’s compatibility with organic polymers makes it perfect for mold release agents, streamlining demolding in production. Aerospace applications count on its capability to minimize rubbing in accuracy components while enduring harsh functional atmospheres.

These materials additionally act as damping fluids in commercial equipment, absorbing vibrations in heavy equipment, and as ingredients in optical fiber finishes to safeguard versus signal loss. Their flexibility, integrated with chemical inertness and environmental stability, positions them as essential components in advancing commercial development and item performance.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid

What are the primary applications of High Viscosity 107 Polymer Hydroxyl Silicone Oil?

High Viscosity 107 Polymer Hydroxyl Silicone Oil is widely used in cosmetics, textiles, and industrial manufacturing. Its thick consistency makes it ideal for creating long-lasting lubricants, mold release agents, and additives for personal care products like hair conditioners and skin creams. The hydroxyl groups enable cross-linking in silicone rubber production, adhesives, and sealants, enhancing durability and flexibility.

What advantages does this silicone fluid offer over alternatives?

This polymer-terminated silicone fluid excels in thermal stability, maintaining performance under high temperatures without degrading. It offers superior lubrication, water resistance, and low volatility, reducing evaporation risks. Its high viscosity ensures long-lasting film formation, making it ideal for protective coatings and applications requiring prolonged material flexibility.

Is this silicone oil safe for cosmetic or medical use?

Yes, it is non-toxic, hypoallergenic, and chemically inert, meeting safety standards for cosmetics and topical formulations. However, always follow industry guidelines for handling, including using proper ventilation and protective equipment during industrial processing to avoid inhalation or skin contact in concentrated forms.

How compatible is it with other materials?

It is compatible with plastics, rubber, metals, and most organic materials. The polymer-terminated structure reduces reactivity, ensuring stability when mixed with other chemicals. Testing compatibility before full-scale use is recommended to avoid unexpected interactions, though it generally resists corrosion or degradation.

What are the storage requirements and shelf life?

Store in a sealed container in a cool, dry place away from direct sunlight or extreme temperatures. Unopened, it has a shelf life of up to 24 months. Avoid contamination by moisture or debris, and ensure containers are tightly closed after use to preserve viscosity and performance. If stored improperly, separation or texture changes may occur.

(High Viscosity 107 Polymer Hydroxyl Silicone Oil Oh Polymer Terminated Silicone Fluid)