Overview of Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

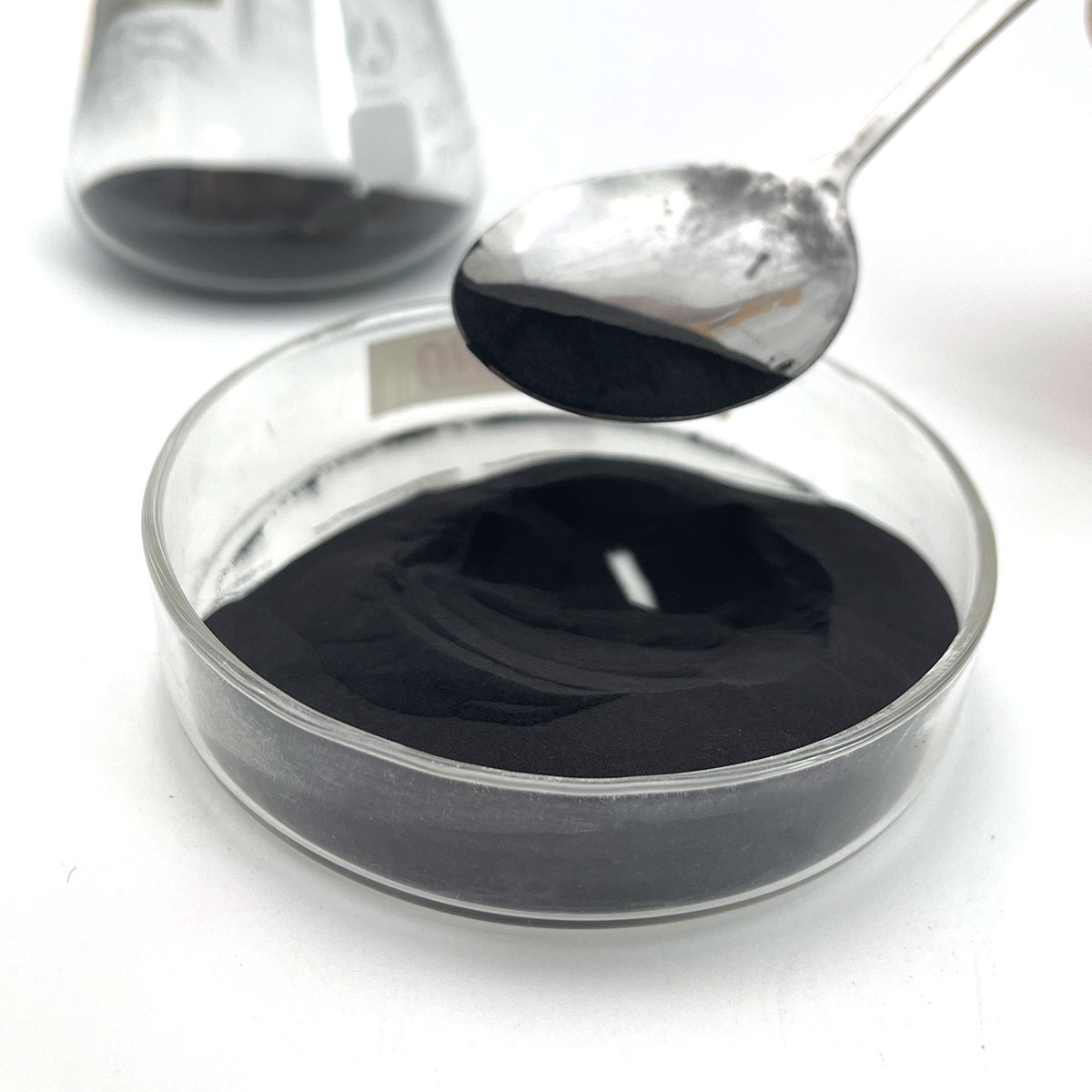

(Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.)

Specification of Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.

Fluorosurfactants are essential ingredients in waterborne and solvent coatings systems due to their ability to lower surface tension and provide excellent adhesion to surfaces. These surfactants can be customized to meet specific requirements, including low surface tension.

One type of fluorsurfactant that is commonly used in waterborne coatings is sodium hydroxide (NaOH). This surfactant has a low surface tension of approximately 15-20 mN/m, which makes it ideal for applications where high levels of surface tension are required. It also provides excellent wetting and emulsification properties, making it an ideal choice for coating applications where the substrate is highly textured or rough.

Another type of fluorsurfactant that is commonly used in solvent coatings is quaternary ammonium compounds (QACs). These surfactants have a low surface tension of around 4-8 mN/m, which makes them ideal for applications where low levels of surface tension are required. They also provide excellent wetting and emulsification properties, making them an ideal choice for coating applications where the substrate is highly textured or rough.

In addition to these two types of surfactants, there are other types of fluorsurfactants available, including aliphatic hydrocarbons, amino acids, and polysaccharides. These surfactants offer a wide range of properties, including increased solubility, reduced foam formation, and improved durability.

Overall, the choice of fluorsurfactant for waterborne or solvent coatings depends on the specific requirements of the application. For example, if high levels of surface tension are required, sodium hydroxide may be the best choice. If low levels of surface tension are required, quaternary ammonium compounds may be the better option. By carefully selecting the appropriate surfactant, manufacturers can ensure that their coatings perform effectively and efficiently, providing optimal protection against wear, tear, and corrosion.

(Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.)

Applications of Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.

Fluorosurfactants are important ingredients in many types of waterborne and solvent coatings systems, due to their ability to create low surface tension that promotes adhesion between the coating and substrates.

One common application of fluorosurfactants is in sealants used on glass surfaces. These coatings are designed to provide a tight, durable bond between the glass and substrate, while also preventing air and water from permeating through. By using fluorosurfactants, manufacturers can achieve high levels of bonding strength without adding significant weight to the coating.

Another use of fluorsurfactants in coatings is in water-based finishes for automotive parts. These coatings can be applied to vehicle bodies, engines, and other components to create a durable, rust-resistant finish that can withstand exposure to water and humidity. Fluoresurfactants help create a low-surface tension that promotes better adhesion between the coating and the surface it is being applied to, resulting in improved resistance to corrosion.

In addition to these applications, fluorsurfactants are also used in various other types of coatings systems, including paint coatings, varnishes, and solvents. For example, some coatings contain fluoride agents that help improve adhesion and durability, while others use polar polymers that form strong, lasting bonds with other materials.

Overall, the benefits of using fluorosurfactants in coatings systems include improved bonding strength, durability, and resistance to corrosion. As such, they are widely used in a variety of industries, including aerospace, automotive, and construction. With advancements in technology and research, the potential uses of fluorsurfactants in coatings systems continue to grow as new innovations emerge.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.

1. What is Fluorosurfactant Low Surface Tension?

: Fluorosurfactant Low Surface Tension (FLST) refers to a type of surfactant that has low surface tension, which means it allows the water to easily flow over surfaces and reduces the resistance of the coating. This makes FLST ideal for use in waterborne or solvent coatings systems.

2. What are the benefits of using FLST for waterborne or solvent coatings?

: The main benefits of using FLST for waterborne or solvent coatings include improved adhesion, reduced viscosity, increased flexibility, and reduced。FLST。

3. How do I determine if I need to use FLST in my coating system?

: To determine if you need to use FLST in your coating system, you should consider the compatibility of the coating with the cleaning and processing conditions used in the industry. If there is significant contact between the coating and solvents, then FLST may be necessary to improve adhesion and reduce viscosity.

4. Can I use FLST in conjunction with other surfactants or chemicals?

: Yes, FLST can be used in conjunction with other surfactants or chemicals in the coating system. However, it’s important to test the combination to ensure optimal performance.

5. Is FLST suitable for all types of coatings systems?

: No, FLST is not suitable for all types of coatings systems. It’s recommended that you choose a surfactant that is compatible with the specific coating application you’re working on.

(Fluorosurfactant Low Surface Tension for Waterborne or Solvent Coatings Systems.)