Overview of Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing

Cationic surfactants are a class of surface-active agents that contain a positively charged head group or cation when dissolved in aqueous solutions. They are characterized by their unique ability to interact with negatively charged surfaces, making them versatile compounds with applications across industries including personal care, household cleaning, textiles, agriculture, and pharmaceuticals. Their positive charge allows for specific interactions with anionic (negatively charged) molecules, which governs their functionality in various formulations.

Features of Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing

-

Positive Charge: The hydrophilic (water-loving) head of a cationic surfactant carries a positive charge, typically derived from ammonium, pyridinium, or quaternary ammonium groups.

-

Strong Binding: Due to their positive charge, they bind strongly to negatively charged surfaces, like those found on skin, hair, or certain bacteria and viruses.

-

Emulsifying & Foaming Properties: Many cationic surfactants are effective emulsifiers, stabilizing oil and water mixtures, and can produce stable foams.

-

Conditioning & Softening: In personal care products, they improve the feel of hair and skin by depositing a conditioning film, enhancing manageability and softness.

-

Antimicrobial Activity: Some cationic surfactants exhibit bactericidal or virucidal properties, making them useful in disinfectants and sanitizers.

-

Compatibility: They can be formulated with other types of surfactants to enhance performance or modify product properties.

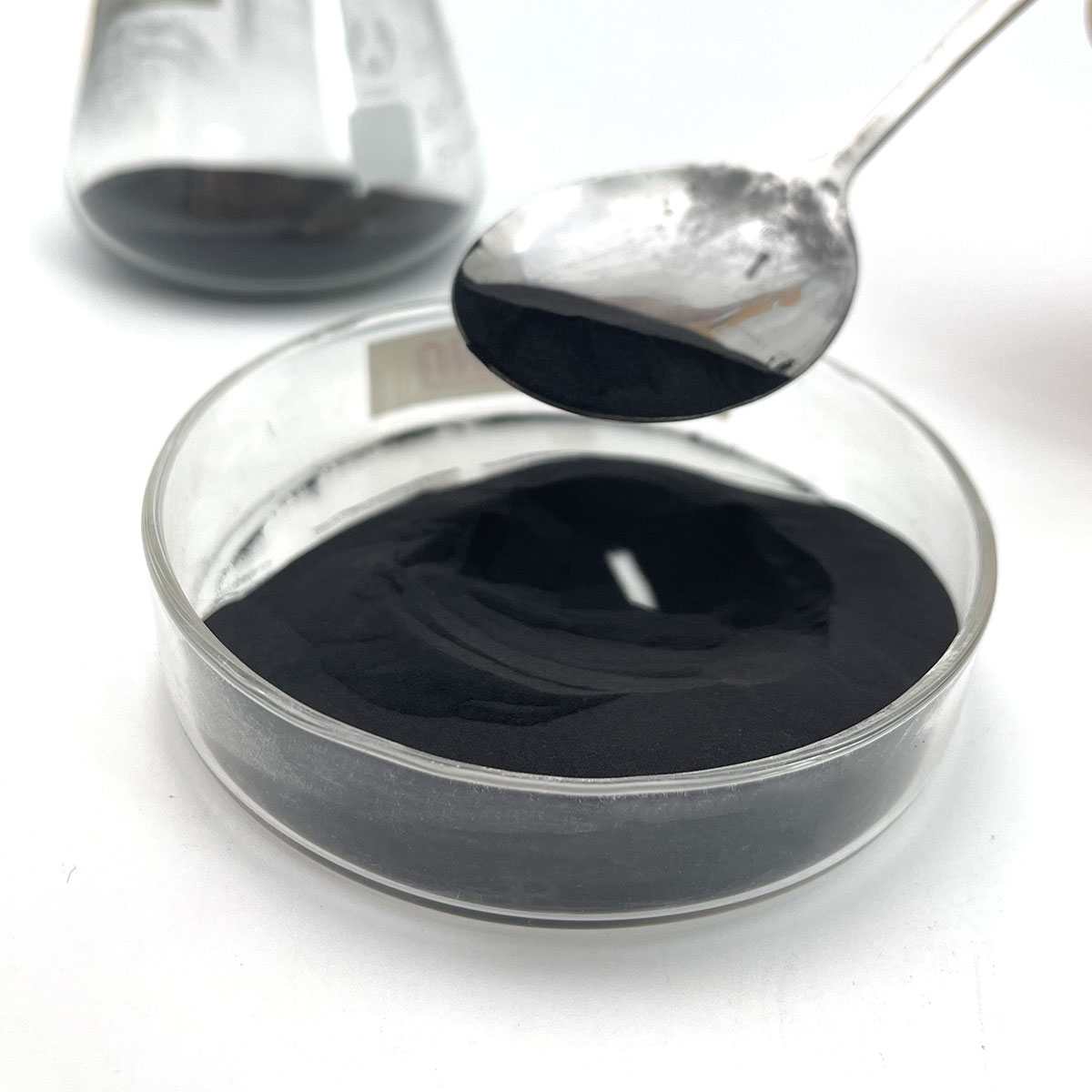

(Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing)

Specification of Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing

Cationic and anionic surface sizing agents play a crucial role in waterproofing applications due to their unique properties. These agents form a protective layer on the surface of films, ensuring they remain water-resistant.

The specific specifications of these chemicals depend on the application requirements. Generally, the size and composition of the Cationic and Anionic Surface Sizing Agents should be carefully optimized to achieve the desired waterproofing properties.

In terms of size, larger particles typically result in greater coverage and better resistance to water. However, this can also lead to clogging issues, as larger particles may block air flow and create more friction between the particles and the surface being covered. Therefore, it is essential to strike a balance between coverage and ease of cleaning.

In terms of composition, the selection of additives such as surfactants, polymers, and antioxidants can also impact the effectiveness of the Cationic and Anionic Surface Sizing Agents. Surfactants help to reduce water absorption and create a barrier against water droplets, while polymers provide durability and resistance to wear and tear. Antioxidants help to prevent the formation of harmful reactive species that can cause damage over time.

When designing the specifications for your Cationic and Anionic Surface Sizing Agent Paper Making Chemicals, it is important to consider factors such as the intended use of the film, the type of film being used (e.g., inkjet or gravure), and the level of humidity and temperature in the environment.

By optimizing the size and composition of your chemicals, you can ensure that your products meet the required waterproofing standards and perform well in different environmental conditions. Additionally, using high-quality materials and providing excellent customer service can help to build long-term relationships with customers and ensure their satisfaction with your products.

(Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing)

Applications of Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing

Cationic and anionic surface sizing agents are widely used in paper making chemicals to improve waterproofing properties of paper products. These agents work by coating the surface of the paper with a protective layer that prevents water from passing through the fibers.

The cationic surface sizing agent is made up of positively charged ions, while the anionic surface sizing agent is made up of negatively charged ions. These oppositely charged ions form a strong bond on the surface of the paper, creating a barrier between the water molecules and the fibers.

By using these surface sizing agents in papermaking chemicals, manufacturers can create waterproofing papers that are more durable and resistant to water damage. This can be particularly important for applications where water exposure is frequent, such as in outdoor applications or in high-traffic areas.

One advantage of using these surface sizing agents is that they do not require any special processing steps to work effectively. Simply mixing them with the paper-making chemicals and allowing them to cure can result in waterproofing papers that are ready for use right away.

Another benefit of these surface sizing agents is that they offer excellent resistance to degradation under heat, light, and other environmental conditions. This makes them ideal for use in applications where temperature changes are significant, such as in clothing, textiles, and packaging materials.

In conclusion, the use of cationic and anionic surface sizing agents in paper making chemicals can significantly improve the waterproofing properties of paper products. By providing a strong barrier between water molecules and the fibers, these agents make it easier to create durable and resistant waterproofing papers that can withstand even the most severe environmental conditions.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing

1. What is the difference between anionic and cationic surface sizing agent?

Anionic surface sizing agents are formed by reacting cations with neutral molecules, resulting in the formation of hydroxides on the surface. Cationic surfacing agents are more effective at reducing water vapor absorption and can improve waterproofing properties.

2. How do cationic surface sizing agents work?

Cationic surfacing agents work by creating a physical barrier that prevents water from passing through. This barrier helps to reduce the amount of moisture that comes into contact with the surfaces being coated.

3. Can cationic surface sizing agents be used on all types of surfaces?

No, cationic surfacing agents are typically formulated for use on concrete, wood, metal, and plastic surfaces. They may not work as well on other materials, so it’s important to test the material first before applying the surfacing agent.

4. Are there any environmental concerns associated with cationic surface sizing agents?

Yes, there are some potential environmental concerns associated with the use of cationic surface sizing agents. The production process involves the use of chemicals, so it’s important to ensure that these chemicals are safe for the environment.

5. Are there any alternatives to cationic surface sizing agents?

Yes, there are several alternatives to cationic surface sizing agents available. Some options include sodium polyacrylate, sodium silicate, and zinc oxide. These alternatives are also effective at improving waterproofing properties, but they may have different chemical properties than cationic surfacing agents.

(Cationic/Anionic Surface Sizing Agent Paper Making Chemicals to Improve Waterproofing)