Overview of Cassava cationic starch manufacturing industrial grade cationic starch

Cationic surfactants are a class of surface-active agents that contain a positively charged head group or cation when dissolved in aqueous solutions. They are characterized by their unique ability to interact with negatively charged surfaces, making them versatile compounds with applications across industries including personal care, household cleaning, textiles, agriculture, and pharmaceuticals. Their positive charge allows for specific interactions with anionic (negatively charged) molecules, which governs their functionality in various formulations.

Features of Cassava cationic starch manufacturing industrial grade cationic starch

-

Positive Charge: The hydrophilic (water-loving) head of a cationic surfactant carries a positive charge, typically derived from ammonium, pyridinium, or quaternary ammonium groups.

-

Strong Binding: Due to their positive charge, they bind strongly to negatively charged surfaces, like those found on skin, hair, or certain bacteria and viruses.

-

Emulsifying & Foaming Properties: Many cationic surfactants are effective emulsifiers, stabilizing oil and water mixtures, and can produce stable foams.

-

Conditioning & Softening: In personal care products, they improve the feel of hair and skin by depositing a conditioning film, enhancing manageability and softness.

-

Antimicrobial Activity: Some cationic surfactants exhibit bactericidal or virucidal properties, making them useful in disinfectants and sanitizers.

-

Compatibility: They can be formulated with other types of surfactants to enhance performance or modify product properties.

(Cassava cationic starch manufacturing industrial grade cationic starch)

Parameter of Cassava cationic starch manufacturing industrial grade cationic starch

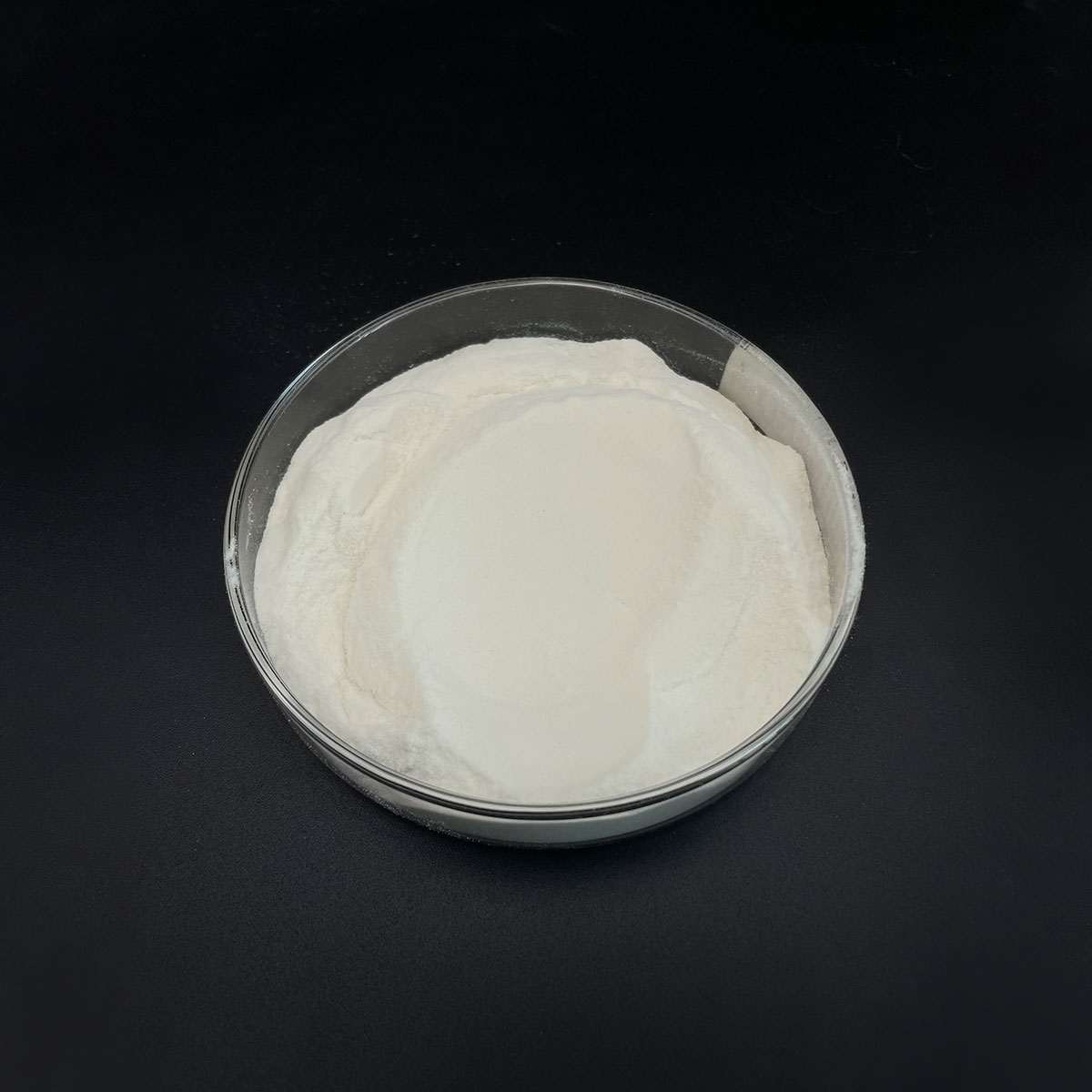

The industrial grade Cationic Starch (SAC) is the highest quality of cassava starch that can be used in food processing and medical applications. The production process involves mixing high-quality cassava with water to form a liquid film, which then undergoes heating,, and drying to produce a fine powder.

Here are some parameters for industrial-grade Cationic Starch:

* Size: The size of the final product is typically between 1-2mm and 300-500μm.

* Contents: The content of the mixture is typically between 70% and 80% of the raw cassava, depending on the specific recipe.

* Processing method: The processing method used for-grade Cationic Starch includes,, and drying.

* Quality control: The quality of the final product is controlled using analytical techniques such as terephthalasyl fluoride analysis, gaseolysis testing, and X-ray imaging.

It’s important to note that there are several other parameters that can affect the overall performance and properties of industrial-grade Cationic Starch, including pH value, moisture content, and cryogenic temperature. These parameters should be carefully controlled during the production process to ensure optimal results.

(Cassava cationic starch manufacturing industrial grade cationic starch)

Applications of Cassava cationic starch manufacturing industrial grade cationic starch

Personal Care Products: Shampoos, conditioners, and skincare products where they serve as conditioning agents, antistatic agents, and sometimes antimicrobials.

Disinfectants and Sanitizers: In formulations designed to kill bacteria and viruses on surfaces due to their microbicidal action.

Textile Treatment: Used as fabric softeners, providing a soft hand feel and static reduction in clothes.

Agriculture: In pesticides and fungicides as adjuvants to improve spreading, sticking, and effectiveness of active ingredients on plant surfaces.

Paper Industry: As retention aids and drainage assistants, improving the paper manufacturing process.

Pharmaceuticals: In topical formulations for their cleansing and soothing properties, and as delivery agents for active pharmaceutical ingredients.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Cassava cationic starch manufacturing industrial grade cationic starch

Q: Is Cassava cationic starch manufacturing industrial grade cationic starch safe for all skin types?

A: While they are widely used, individuals with sensitive skin might experience irritation or allergic reactions. It’s essential to follow product instructions and patch test when trying new products.

Q: Can Cassava cationic starch manufacturing industrial grade cationic starch be combined with anionic surfactants?

A: Mixing cationic and anionic surfactants often results in precipitation due to charge neutralization, but specific combinations at controlled ratios can be formulated to achieve desired properties without precipitation.

Q: How does Cassava cationic starch manufacturing industrial grade cationic starch contribute to antimicrobial activity?

A: The positive charge of cationic surfactants interacts with the negatively charged cell walls of many microorganisms, disrupting their membrane integrity, leading to cell lysis and death.

Q: Is Cassava cationic starch manufacturing industrial grade cationic starch biodegradable?

A: Biodegradability varies among cationic surfactants. Quaternary ammonium compounds, a common type, can be less biodegradable, but efforts are ongoing to develop more eco-friendly alternatives.

Q: What makes Cassava cationic starch manufacturing industrial grade cationic starch effective as fabric softeners?

A: They deposit on fabric fibers during the rinse cycle, neutralizing static charges, reducing friction between fibers, and providing a softer feel.

(Cassava cationic starch manufacturing industrial grade cationic starch)