Overview of Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

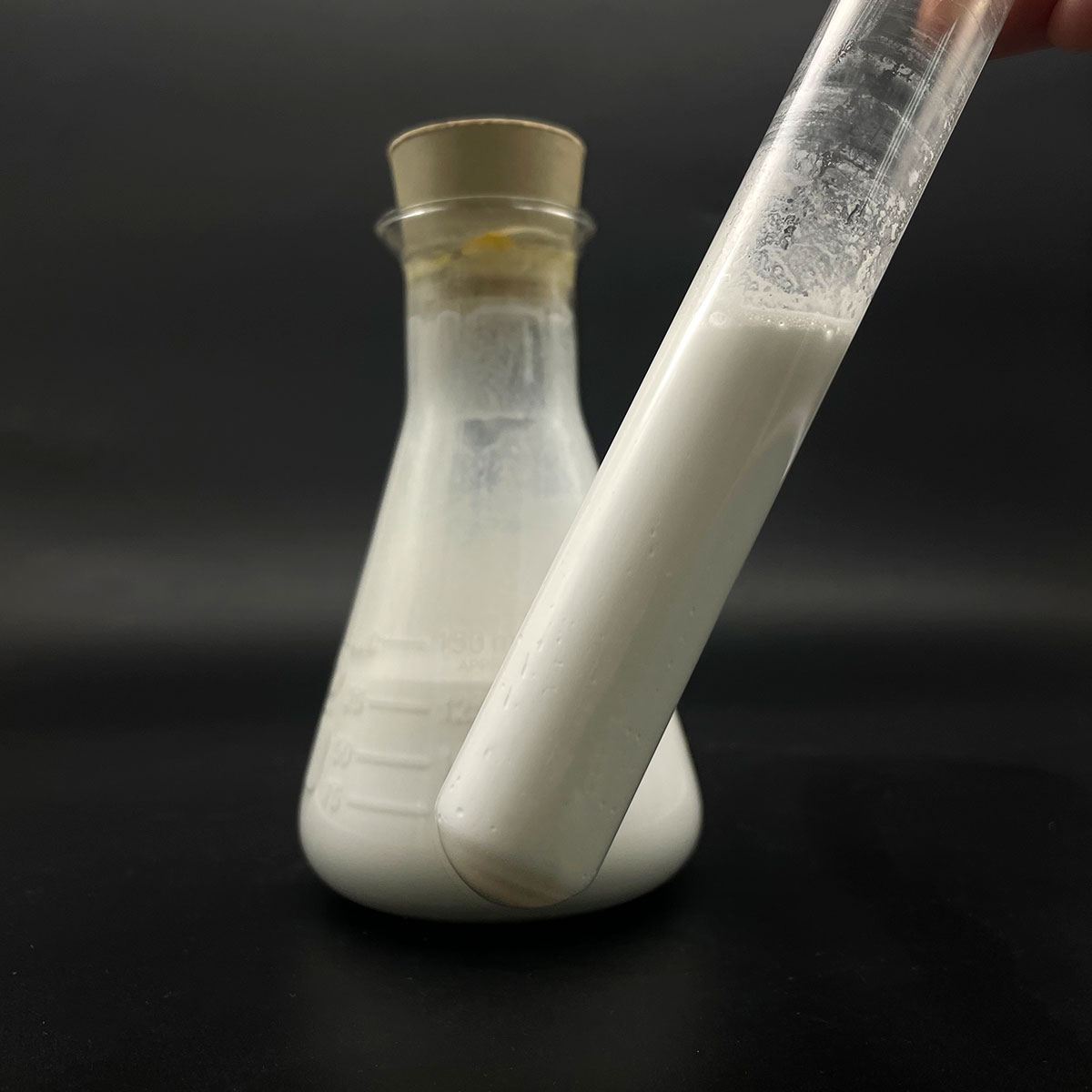

(Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant)

Parameters of Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant

The parameter of the Anionic Polyacrylamide flocculant Special Slime Wastewater polymer used in coal washing plants depends on various factors such as the type of slag produced, the specific requirements of the washing process, and the overall water quality standards.

For example, if the production process involves washing the slag using hot water or other aggressive methods, then the parameter may be set higher to increase the chances of sedimentation and mineral separation. Additionally, the desired size and size distribution will also impact the particle-to-volume ratio of the polymer, which in turn affects its ability to effectively absorb and remove impurities from the waste water.

Overall, it is important to carefully evaluate the parameters of the anionic polyacrylamide flocculant special slime wastewater polymer used in coal washing plants to ensure that it meets the specific needs of the application. This may involve performing calculations based on the characteristics of the slag, as well as the specific environmental conditions and washing processes being performed.

(Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant)

Applications of Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant

-

Personal Care and Cosmetics: As emulsifiers, thickeners, and stabilizers in creams, lotions, and shampoos, offering improved aesthetics and performance.

-

Drug Delivery: Formulation of nanoparticles, microcapsules, and hydrogels for targeted and controlled drug release, enhancing therapeutic efficacy and patient compliance.

-

Oilfield Chemicals: Enhanced oil recovery, drilling fluids, and demulsifiers due to their superior stability and ability to function in harsh conditions.

-

Food Industry: As emulsifiers and stabilizers in food products, improving texture, shelf-life, and the delivery of flavors and nutrients.

-

Water Treatment: In wastewater treatment processes for flocculation, clarification, and the removal of pollutants.

-

Paints and Coatings: As dispersants and rheology modifiers, improving pigment dispersion, stability, and application properties of paints and coatings.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant

Q: Is Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant more expensive than conventional surfactants?

A: Generally, yes, due to its complex synthesis and higher functionality. However, their enhanced performance and often justify the added cost.

Q: Is Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant biocompatible?

A: Many polymer surfactants are designed to be biocompatible and suitable for biomedical applications, but compatibility tests are essential for specific uses.

Q: How does Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant differ in their environmental impact compared to small molecule surfactants?

A: Polymer surfactants, especially those designed to be biodegradable, can have a lower environmental impact due to slower release and reduced accumulation in ecosystems.

Q: Can Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant be used in all types of formulations?

A: Their use depends on the specific formulation requirements. Compatibility, solubility, and interaction with other components need to be considered for successful integration.

Q: Is Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant effective in extreme conditions?

A: Yes, their high molecular weight often provides stability in harsh environments like high temperatures, high salinity, or extreme pH, where conventional surfactants may degrade.

(Anionic Polyacrylamide Flocculant Special Slime Wastewater Polymer for Coal Washing Plant)