Title: How Surfactants Stabilize Colloidal Suspensions

(How Do Surfactants Stabilize Colloidal Suspensions)

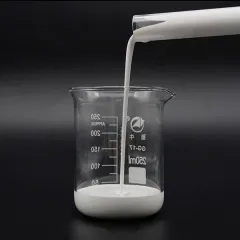

Abstract: The surfactant industry has revolutionized the way we create solutions to various problems in our daily lives. Among these, colloidal suspensions play an essential role in many industries such as pharmaceuticals, food processing, cosmetics, and others. However, colloidal suspensions can be stable even when subjected to high temperatures or pressures. This article explores how surfactants stabilize colloidal suspensions and its applications.

Introduction:

Colloidal suspensions are made up of droplets or particles that are suspended in water due to the presence of colloidal particles such as sodium ions, amino acids, and lipids. They are commonly used in industries where large quantities of liquid is needed to transfer into another container or vessel without impacting the performance of the product. Surfactants, particularly hydroxyl esters, are effective in stabilizing colloidal suspensions by their ability to form solutes that provide a good packing effect for the colloidal particles.

Key Factors Influencing the Stability ofcolloidal suspensions:

There are several factors that influence the stability of colloidal suspensions, including:

1. Size and type of colloidal particles: The size and type of colloidal particles affect their ability to interact with each other and stabilize the suspension. For example, larger particles may need more surface area for maximum contact between them and the solution, while smaller particles may require fewer surface areas.

2. Solubility: The solubility of a surfactant also affects its stability of colloidal suspensions. A solubilant needs to be able to dissolve in water at low pH levels provide sufficient coverage for colloidal particles to settle down and become.

3. Temperature and pressure: The stability of colloidal suspensions can be influenced by temperature and pressure. If the temperature increases too quickly, the reaction rate of the surfactant may increase, which could lead to the instability of the suspension. On the other hand, if the pressure is increased too slowly, the reaction rate of the surfactant may decrease, leading to the stability of the suspension.

Why Surfactants Stabilize Colloidalations:

Surfactants, particularly hydroxyl esters, act by forming solutes that provide a good packing effect for colloidal particles. When a surfactant is added to a colloidal suspension, it creates a film or network of molecules that helps to encapsulate the colloidal particles and prevent them from settling. This helps to ensure the stability of the suspension over time.

In addition to solubilant properties, surfactants can also play a role in stabilizing colloidal suspensions by reducing the surface tension of the solution. This reduces the amount of force required to overcome the tension at which the colloidal particles are placed, leading to the stability of the suspension.

Application of Surfactants to Colloidalations:

Surfactants are widely used in various industries where colloidal suspensions are necessary. For instance, in the pharmaceutical industry, surfactants are used to stabilize insulin crystals, glaucomia, and heart failure medications. In the food processing industry, surfactants are used to stabilize enzymes in raw materials and to prevent food from sticking together during processing. In the cosmetic industry, surfactants are used to stabilize ingredients in skin care products and in toothpaste.

Conclusion:

(How Do Surfactants Stabilize Colloidal Suspensions)

Surfactants have revolutionized the way we produce solutions to various problems in our daily lives. Their ability to stabilize colloidal suspensions provides us with a wide range of applications, ranging from drug delivery systems to industrial cleaning solutions. Understanding how surfactants stabilize colloidal suspensions is crucial for developing new technologies and improving the overall performance of industrial processes.