Transline is a global oil and gas company that operates in various regions around the world. The company has been in operation for over 50 years and has become one of the largest oil and gas companies in the world. One of the key components of Transline’s operations is the use of chemicals, including surfactants.

(Does Transline Require Surfactant)

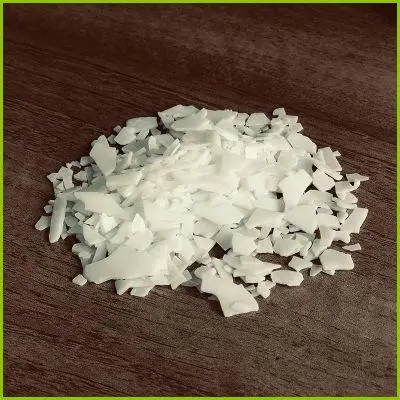

Surfactants are chemicals that reduce the surface tension between two liquids or between two surfaces to improve their flow properties. They are used in many different applications, including cleaning, thickening, and dissolving fluids. Surfactants are essential to many of the processes that make up modern life.

One of the most common types of surfactants is polyvinylpyradecanoic acid (PVP). PVP is anionic surfactant and is commonly used in personal care products such as shampoo and soap. It works by reducing the surface tension between the oils and water in the mixture, allowing them to easily mix together and form a lather.

Another type of surfactant that is widely used in the oil and gas industry is alkylphenol ethoxylate (APEX). APEX is non-ionic surfactant and is often used in oil recovery processes to remove oil from underground formations. It works by reducing the surface tension between the hydrocarbons and water, making it easier to extract the oil.

In addition to these types of surfactants, Transline also uses other chemicals in its operations, including detergents and corrosion inhibitors. These chemicals work together to help protect the equipment and prevent damage from occurring during operation.

Despite the wide range of applications in which surfactants are used, there is still ongoing debate about the efficacy of certain types of surfactants in different environments. For example, some studies have suggested that some surfactants may be less effective in harsh conditions, while others have found that certain types of surfactants may have more toxic effects on human health.

As a result, Transline must carefully consider the appropriate choice of surfactant for its operations. This includes weighing the potential benefits against the risks, taking into account factors such as cost, ease of production, and environmental impact. In many cases, Transline will select the most effective type of surfactant based on a combination of scientific research and market analysis.

(Does Transline Require Surfactant)

In conclusion, the use of surfactants in Transline’s operations plays a crucial role in ensuring that the company can operate efficiently and effectively in a variety of environments. By carefully considering the appropriate choice of surfactant, Transline can maximize the benefits of this important chemical component while minimizing the risks associated with its use.