Overview of Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

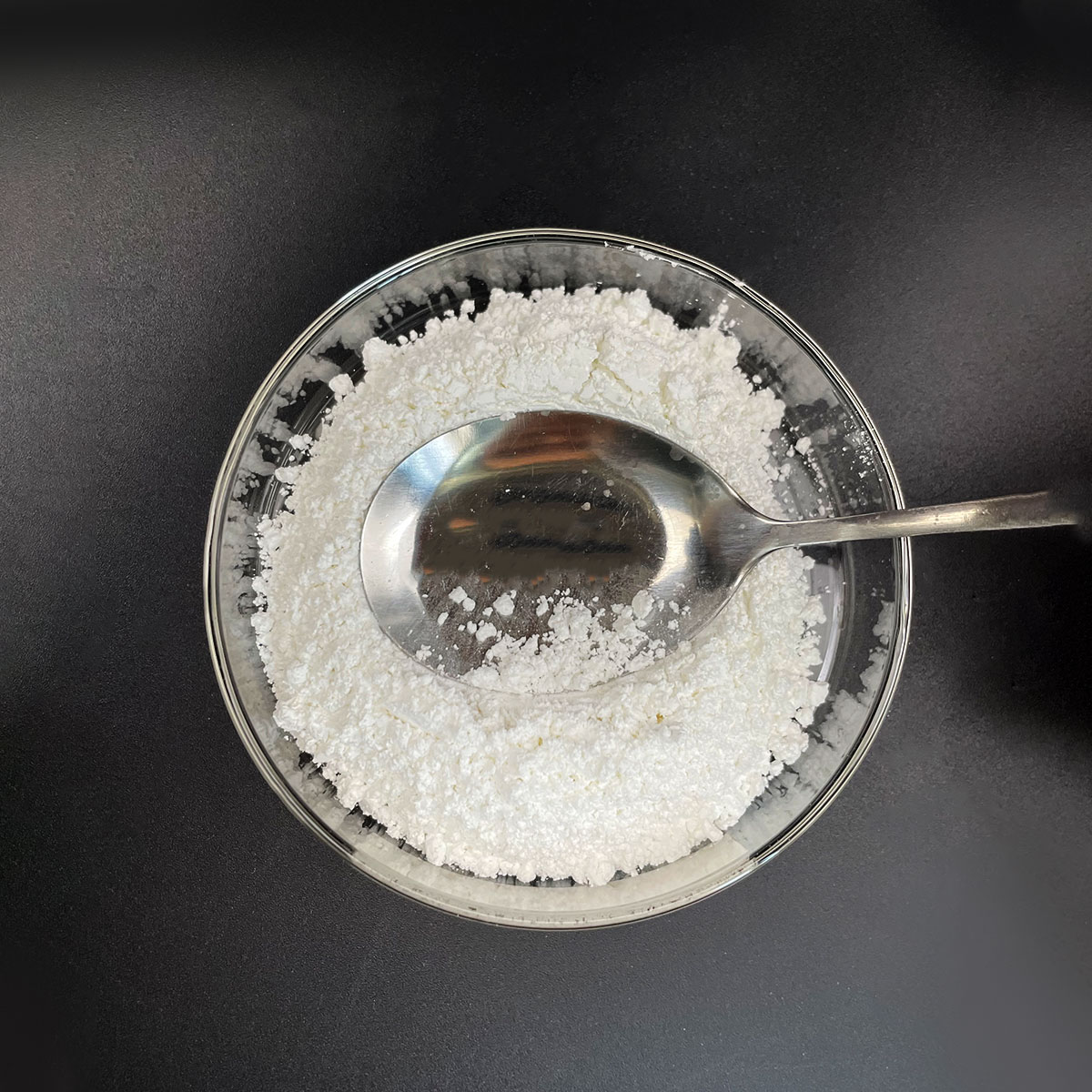

(Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%)

Specification of Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%

Polyol, Polymer Polyol (POP), and POP with differing polymer web content (10%, 13%, 15%, 25%, 45%) are crucial basic materials utilized in the manufacturing of adaptable and stiff polyurethane foams. These items are created to boost efficiency qualities such as load-bearing capacity, toughness, and foam stability. Below are the essential requirements and features of these materials:

** Polyol **: A base polyol is a hydroxyl-rich compound, generally derived from petroleum or bio-based sources, functioning as the main element in polyurethane systems. It provides outstanding reactivity, compatibility with additives, and flexibility in foam formulations. Secret specifications consist of hydroxyl value (OHV) varying from 28– 56 mg KOH/g, thickness in between 300– 6000 mPa · s( relying on grade), and low level of acidity (pH ~ 6– 9).

** Polymer Polyol (POP) **: POP is a modified polyol containing dispersed polymer fragments (e.g., styrene-acrylonitrile or SAN) to boost foam hardness and structural stability. The polymer material straight influences performance. As an example:

– ** POP 10%**: Consists of 10% polymer solids, offering modest reinforcement for semi-flexible foams. OHV: 48– 56 mg KOH/g; viscosity: 1500– 2500 mPa · s.- ** POP 13%**: Balanced for furniture and automobile seats. OHV: 44– 52 mg KOH/g; viscosity: 2000– 3500 mPa · s.- ** POP 15%**: Greater load-bearing capacity for mattresses. OHV: 40– 48 mg KOH/g; viscosity: 2500– 4000 mPa · s.- ** POP 25%**: Optimized for rigid applications and high-resilience foams. OHV: 32– 40 mg KOH/g; viscosity: 3500– 5000 mPa · s.- ** POP 45%**: Ultra-high polymer content for industrial usages, giving outstanding resilience. OHV: 24– 30 mg KOH/g; viscosity: 4000– 6000 mPa · s.

All grades include low tide web content (

(Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%)

Applications of Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%

Polyol, Polymer Polyol (POP), and versions with varying polymer content (10%, 13%, 15%, 25%, 45%) are versatile materials commonly utilized in polyurethane (PU) production. These components function as the foundation for creating adaptable, semi-flexible, and stiff foams, satisfying varied industries because of their tunable residential properties.

** Flexible Foams (10%-15% Polymer Content): ** Lower polymer web content POP (10%-15%) is perfect for flexible PU foams utilized in furnishings, mattresses, and auto seats. These foams prioritize comfort, breathability, and resilience, providing well balanced support for applications like sofa cushions, bedding, and safety seat. The 15% variant enhances longevity while maintaining gentleness, making it appropriate for high-use furnishings and ergonomic products.

** Semi-Flexible Foams (25% Polymer Material): ** POP with 25% polymer content is crafted for semi-flexible foams that call for higher load-bearing capability and vibration dampening. Applications include auto interior elements (headrests, armrests, control panels) and industrial cushioning. This quality offers structural security and sound reduction, critical for enhancing automobile convenience and security.

** High-Performance Stiff Foams (45% Polymer Web Content): ** POP with 45% polymer content is customized for rigid foams utilized in insulation, building and construction, and refrigeration. These foams provide remarkable thermal resistance, dimensional stability, and mechanical toughness, making them ideal for insulating panels, fridges, and cold storage systems. The high polymer web content guarantees power efficiency and lasting efficiency in severe temperatures.

** Specialized Applications: ** All grades are utilized in footwear (midsole padding), adhesives, coverings, and elastomers. Reduced polymer grades (10%-15%) match light-weight sports shoes, while greater qualities (25%-45%) enhance longevity in commercial adhesives or water-proof coverings.

** Sustainability: ** Several polyol/POP formulations now incorporate bio-based or recycled material, lining up with green production trends. Their flexibility sustains circular economy goals by making it possible for recyclable PU items.

In summary, polyol and POP qualities (10%-45%) make it possible for customized remedies throughout industries– from comfort-driven durable goods to high-performance industrial systems. By readjusting polymer material, suppliers enhance foam thickness, elasticity, and stamina, making certain items fulfill details functional and sustainability needs.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%

**What are Polyol and Polymer Polyol (POP), and how do they differ?**

Polyols are base chemicals used to produce polyurethanes, reacting with isocyanates to create foams, coatings, or elastomers. Polymer Polyol (POP) is a modified polyol infused with polymer particles (like styrene-acrylonitrile) to enhance foam properties such as firmness and load-bearing capacity. The key difference is that POP contains dispersed polymer solids, improving performance compared to conventional polyols.

**What do the percentages (10%, 13%, 15%, 25%, 45%) in POP mean?**

These percentages indicate the concentration of polymer solids within the polyol blend. For example, POP 10% contains 10% polymer particles by weight, while POP 45% has 45%. Higher percentages mean more polymer content, directly influencing foam density, hardness, and structural integrity.

**What applications suit different POP percentages?**

Lower polymer content (10%-15%) is ideal for flexible, soft foams like mattress toppers or cushioning. Mid-range (15%-25%) balances comfort and support for furniture or automotive seating. High-percentage POP (25%-45%) is used for rigid, durable applications such as high-resilience foam in heavy-duty seating, insulation panels, or industrial components requiring structural strength.

**How does polymer content affect foam properties?**

Higher polymer content increases load-bearing capacity, tensile strength, and durability while reducing foam shrinkage. For instance, POP 45% creates denser, firmer foam with superior resistance to deformation, whereas lower percentages yield softer, more flexible foams. The choice depends on balancing comfort, cost, and performance requirements.

**How should Polyol/POP be handled and stored?**

Store in sealed containers at 15-30°C, away from moisture and direct sunlight. Avoid contamination with water or solvents, as this can disrupt reactions with isocyanates. Use PPE (gloves, goggles) during handling. Ensure proper ventilation to prevent vapor buildup. Shelf life is typically 6-12 months; check manufacturer guidelines for specifics. Mix thoroughly before use to ensure polymer dispersion.

(Polyol/Polymer Polyol/Pop/Pop 10% 13% 15% 25% 45%)