Title: “The Art of Thickening Low-Surfactant Concentrations: A Journey Through Strategies”

(Strategies for Thickening Low-Surfactant Concentration Systems)

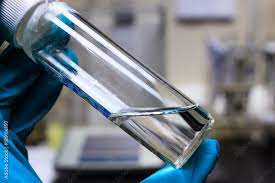

As someone who works in the field of chemical engineering, I am always on the lookout for new ways to improve the performance of low-surfactant concentration systems. This is especially true when it comes to thickening processes, where the desired outcome is not just increased flow but also increased yield.

In this blog post, we will explore some of the most effective strategies for thickening low-surfactant concentrations. Whether you’re working on a lab experiment or an industrial plant, these strategies can help you achieve your goals and optimize your process.

First and foremost, it’s important to understand what makes a good thickener. A good thickener should have a high surface area, which allows for efficient absorption of solvents and fats. Additionally, it should be able to dissolve small molecules, such as proteins and polymers, without causing significant resistance or fouling.

One strategy that has been widely used for centuries is called sieving. Sieving involves passing the solution through a series of sieve plates, each of which is designed to remove a different size of particles from the mixture. As the particles pass through the sieve plates, they become smaller and smaller until they pass completely through, leaving behind larger particles that are difficult to remove. By repeating this process multiple times, you can create a sieved layer that effectively removes small molecules from the solution.

Another popular method for thickening low-surfactant concentrations is called fractional distillation. Fractional distillation involves passing a portion of the mixture through a heat exchanger, followed by separation of the fluid into two streams using a column or. The fractional distillation process allows for more efficient use of resources, as only a portion of the material is passed through each stage. It also produces a purer product, as impurities are separated before passing through the next stage.

There are many other strategies that can be used for thickening low-surfactant concentrations, including microfiltration, ultrasound therapy, and chemical vapor deposition (CVD). Each of these methods has its own advantages and disadvantages, and the best approach depends on the specific requirements of the system being optimized.

(Strategies for Thickening Low-Surfactant Concentration Systems)

In conclusion, there are many effective strategies for thickening low-surfactant concentrations. By understanding what makes a good thickener and choosing the right method for your needs, you can optimize your process and achieve the desired outcomes. Whether you’re working on a lab experiment or an industrial plant, these strategies can help you get ahead in your career and stay ahead of the curve in the ever-changing world of chemical engineering.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)