Overview of Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052)

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052)

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

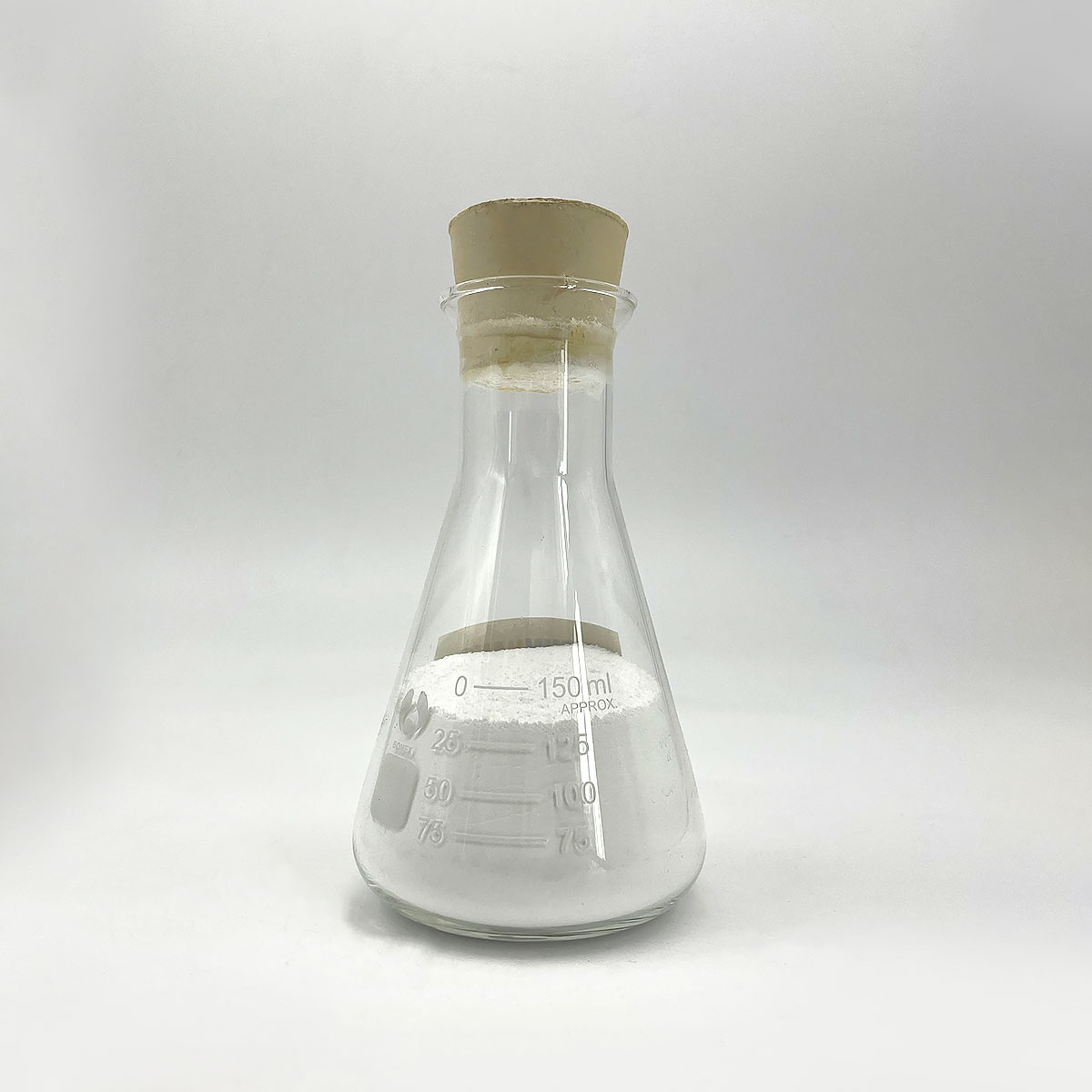

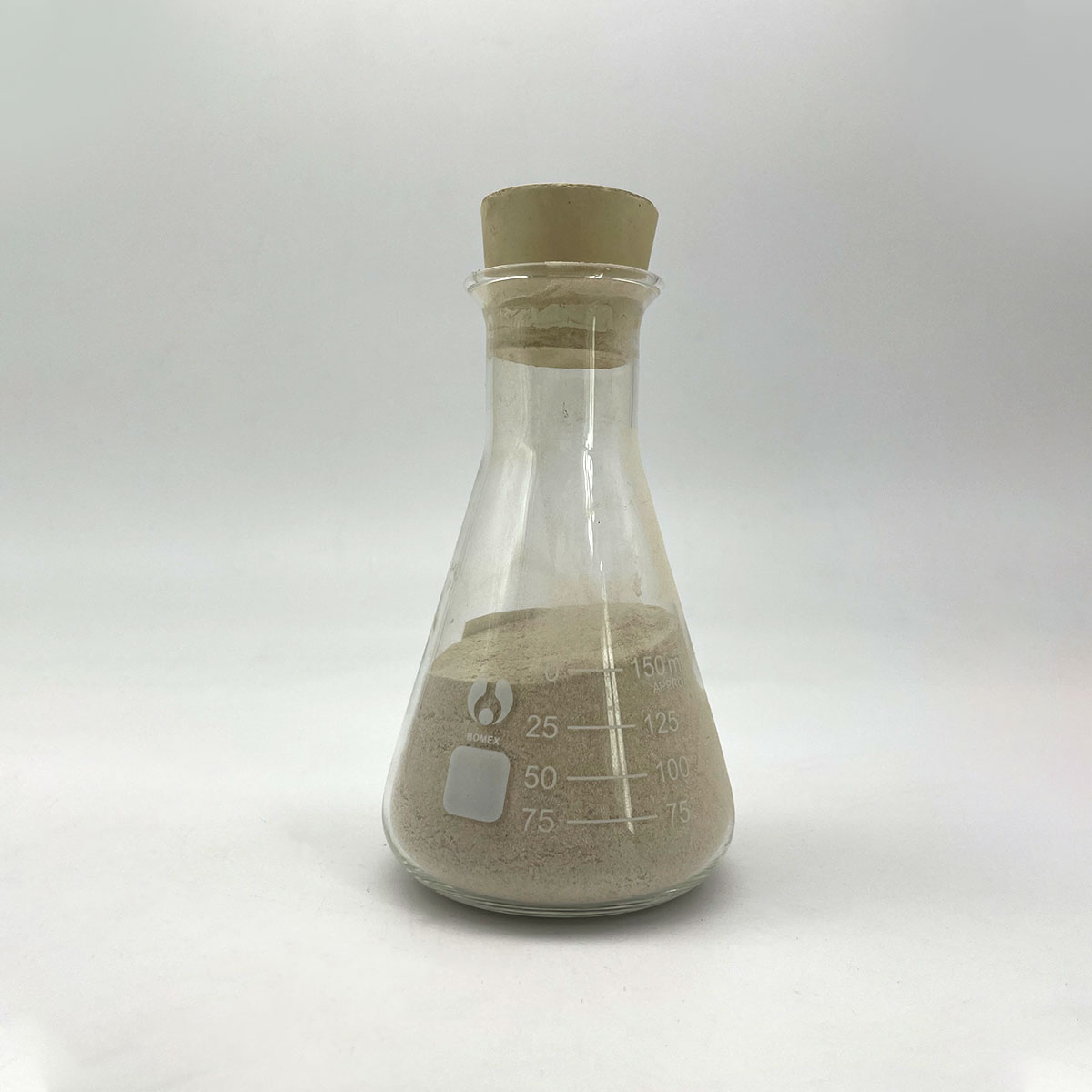

(Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052))

Specification of Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052)

The DF052 is a specification for minimal impact on gloss special polyether defoamer for high viscosity coatings. It is designed to meet the requirements of manufacturers looking for an efficient and effective product that can minimize damage to their coating systems while maintaining excellent gloss and clarity.

One of the key features of the DF052 is its low viscosity, which allows it to be easily complex coatings and without causing significant build-up or coagulation. This makes it particularly useful in applications where there is a need to remove excess coating from the substrate, such as paint finishing or varnish treatment.

Another important aspect of the DF052 is its compatibility with a wide range of substrates, including a variety of materials such as metal, plastic, glass, and. The manufacturer has carefully selected the appropriate materials and formulated the defoamer to ensure that it works effectively on all surfaces.

The DF052 also contains a range of additives that help to prevent corrosion and maintain the surface integrity of the coating. These additives include antioxidants, anti-corrosion agents, and surfactants that work together to protect the coating from the effects of moisture, wear and tear, and other environmental factors.

Overall, the DF052 is a specification for minimal impact on gloss special polyether defoamer for high viscosity coatings that offers excellent performance and reliability. Its low viscosity, compatibility with a wide range of substrates, and advanced additives make it an ideal choice for manufacturers seeking to improve the efficiency and effectiveness of their coating systems.

(Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052))

Applications of Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052)

Minimizing impact on gloss special polyether defoamer for high viscosity coatings (DF052) is an essential aspect of achieving optimal performance in various industries. The df052 is designed to be a minimal-impact formula, meaning that it reduces the amount of chemical reactions and other adverse effects associated with traditional defoamers.

One of the key benefits of using df052 is its ability to effectively clear and smooth paint surfaces without leaving any residue or damage. This is particularly important in applications where there may be strict tolerances for surface finish and consistency, as even small amounts of contamination can lead to noticeable imperfections in the final product.

In addition to its effectiveness at reducing chemical impact, df052 is also environmentally friendly. Its low viscosity makes it ideal for use in a variety of environmental applications, including water-based paints and coatings. This means that df052 can help reduce waste and minimize its environmental impact compared to traditional defoamers.

Another benefit of df052 is its durability. Because it contains less volatile organic compounds (VOCs), df052 is less likely to evaporate or leave behind any residue during application. This helps to prolong the life of the coating and improve its overall performance.

Overall, df052 is an excellent choice for those looking to achieve optimal results in their applications while minimizing negative impacts on the environment. Its effectiveness, eco-friendliness, and durability make it a top choice among professionals in the paint and coatings industry.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052)

1. What is DF052?

DF052 is a highly effective and minimal impact polyether defoamer designed specifically for high viscosity coatings.

2. How does DF052 work?

DF052 works by breaking down the polymer network in the coating, allowing it to flow more easily through the nozzle and achieve better coverage.

3. Is DF052 safe for use in high-temperature applications?

DF052 is safe for use in high-temperature applications, as long as it is used according to the manufacturer’s instructions.

4. Can DF052 be used with all types of coatings?

DF052 can be used with a wide range of high-temperature coatings, including epoxy, silicone, and varnishes.

5. Are there any limitations to using DF052?

There are some limitations to using DF052, such as its relatively high cost compared to other defoamers. Additionally, it may not be suitable for all types of coatings or may require careful testing to ensure optimal performance.

(Minimal Impact on Gloss Special Polyether Defoamer for High Viscosity Coatings (DF052))