Overview of chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent

Nonionic surfactants are a class of surface-active agents that do not carry an electrical charge in aqueous solutions, distinguishing them from ionic surfactants like cationics and anionics. They are composed of a hydrophilic (water-loving) head group and a hydrophobic (oil-loving) tail, which allows them to reduce surface tension between fluids and facilitate interactions between substances that are normally immiscible. Their neutrality makes them stable over a wide pH range and compatible with other types of surfactants, making them highly versatile in numerous applications.

Features of chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent

-

Neutral Charge: Lack of charge leads to compatibility with both anionic and cationic substances, reducing the risk of precipitation or instability in formulations.

-

Wide pH Stability: Function effectively across a broad pH range, making them suitable for diverse chemical environments.

-

Solubility: Readily soluble in both water and organic solvents, enhancing their utility in cleaning, emulsification, and dispersion processes.

-

Low Foam Profile: Many nonionic surfactants generate less foam compared to their ionic counterparts, beneficial in applications where excessive foam is undesirable.

-

Wetting and Spreading: Excellent at reducing surface tension, promoting wetting and spreading of liquids on surfaces, improving cleaning and coating processes.

-

Emulsification: Efficiently stabilize oil-in-water or water-in-oil emulsions, depending on their structure, which is crucial in formulations like cosmetics, agrochemicals, and food products.

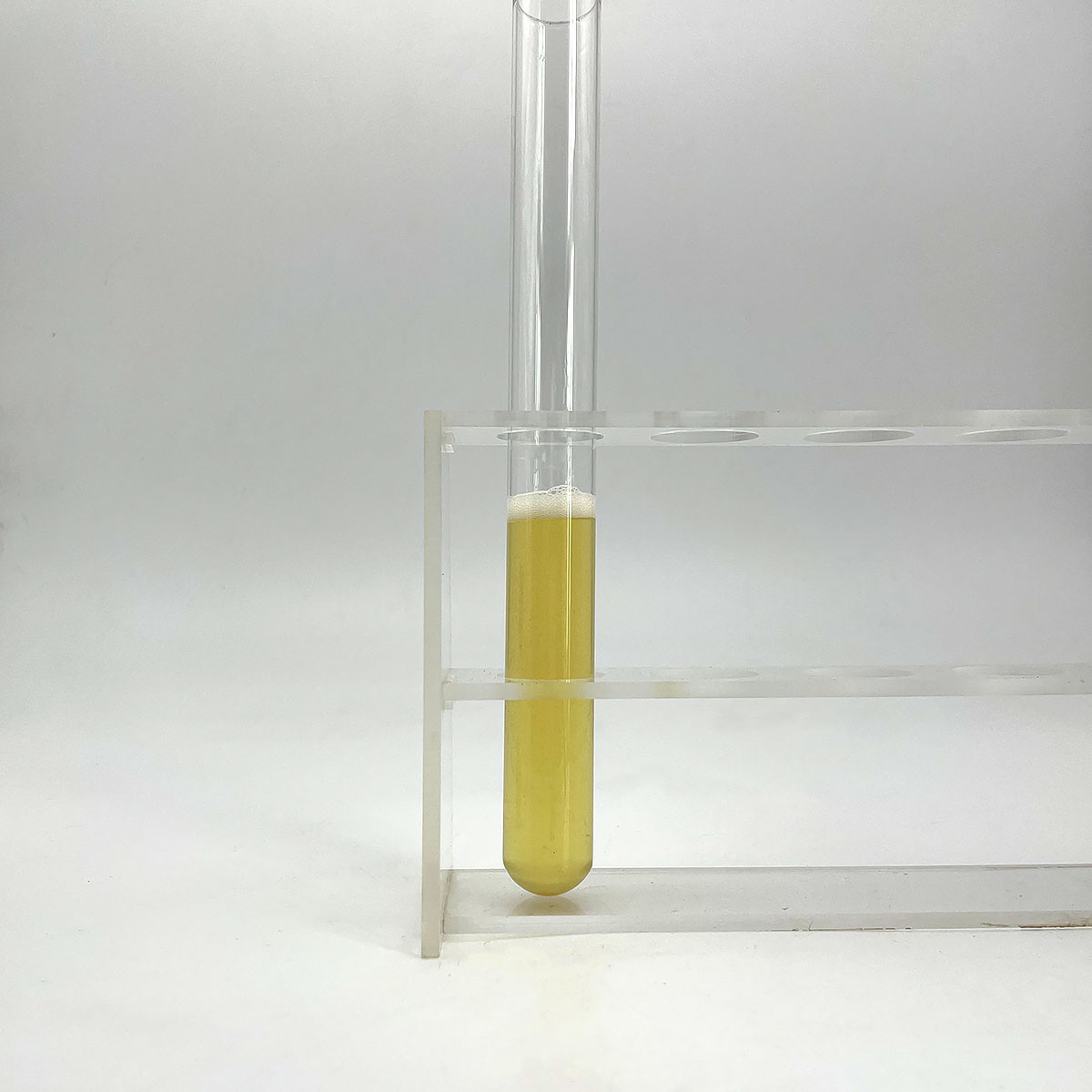

(chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent)

Parameter of chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent

The parameter that affects the performance of chemical nonionic polyacrylamide (PAM) as a thickening agent in coal washing mine tailings is its concentration and the type of fabrication method used to make the PAM solution. The concentration of PAM can be adjusted by varying the amount of PAM added to the water, while the type of fabrication method can affect the surface tension of the fabric and thus the rate at which PAM spreads through it.

The surface tension of a material is affected by various factors such as the size of the particles, their shape, and the presence of functional groups on their surfaces. In the case of coal washing mine tailings, the fabrication method can also affect the adsorption efficiency of PAM onto the surface of the tailings. For example, using electrostatic adsorption or surface ionization methods may result in better adsorption efficiency compared to chemical precipitation methods.

In addition, the temperature and pH of the water used to prepare the PAM solution can also impact its performance as a thickening agent. Higher temperatures can accelerate the degradation of the PAM, while lower temperatures can result in more prolonged adsorption time.

Overall, the optimal parameter combination for using PAM as a thickening agent in coal washing mine tailings will depend on the specific conditions of the application and the desired outcome. A thorough understanding of these parameters and their effects on the performance of PAM as a thickener is necessary to optimize its use in this context.

(chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent)

Applications of chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent

-

Household and Industrial Cleaning: Found in detergents, dishwashing liquids, and hard surface cleaners for their effective cleaning and low-foaming properties.

-

Personal Care Products: Used in shampoos, lotions, and creams as emulsifiers and solubilizers, contributing to product texture and stability.

-

Textile Industry: In textile processing for dyeing, finishing, and softening fabrics, improving color yield and feel.

-

Agriculture: As components of pesticide formulations, helping to disperse and stabilize active ingredients on leaf surfaces.

-

Food Industry: Approved nonionic surfactants are used as emulsifiers and stabilizers in food products like mayonnaise and ice cream.

-

Paints and Coatings: Essential for dispersing pigments, improving flow properties, and enhancing film formation in paint formulations.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent

Q: Is chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent biodegradable?

A: Biodegradability varies; many nonionic surfactants are designed to be biodegradable to minimize environmental impact, but it’s important to check specific product labels.

Q: Why is chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent used in low-foaming applications?

A: Their molecular structure tends to produce less foam than ionic surfactants, making them suitable for applications where foam could interfere with processes or cleaning effectiveness.

Q: Can chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent be used in hard water conditions?

A: Yes, their performance is generally not affected by the presence of minerals in hard water, unlike some ionic surfactants that can precipitate.

Q: How do chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent affect the skin?

A: Generally, they are considered mild and less irritating than ionic surfactants, making them popular in personal care products.

Q: Are all nonionic surfactants soluble in cold water?

A: Not necessarily. While many nonionic surfactants are cold-water soluble, some may require warmer temperatures to fully dissolve or exhibit optimal performance.

(chemical nonionic polyacrylamide PAM for coal washing mine tailing thickening agent)